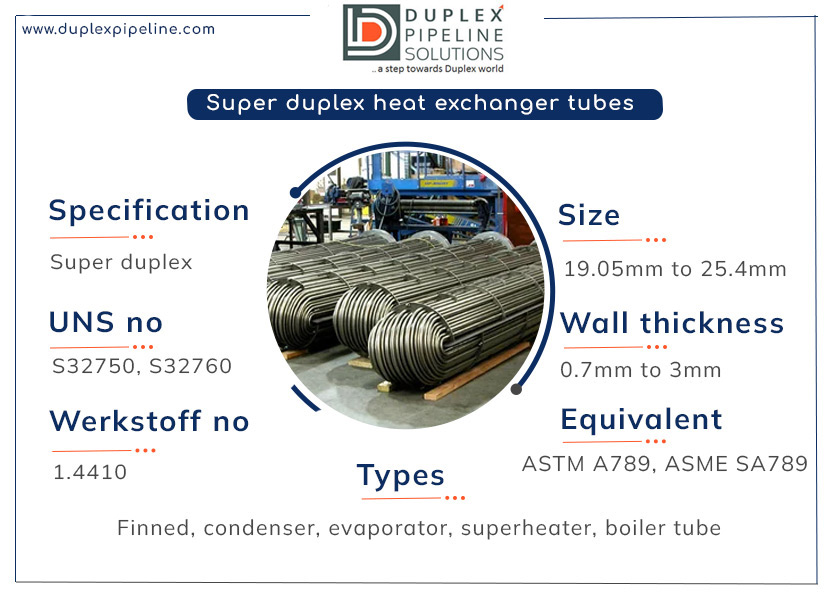

Super Duplex Heat Exchanger Tubes

How do Super Duplex Heat Exchanger Tubes perform in low-temperature applications?

Super Duplex heat exchanger tubes deliver outstanding performance in low-temperature conditions, offering a dependable mix of durability, strength, and corrosion protection even in freezing or sub-zero settings. Unlike certain stainless steels that may become fragile in cold climates, Super Duplex retains solid impact resistance and mechanical stability, making it ideal for cryogenic or chilled environments.

Thanks to its dual-phase structure (ferritic and austenitic), Super Duplex provides superior resistance to brittle failure-an essential feature in industries such as offshore, oil and gas, LNG, and chemical processing, where equipment is often exposed to sudden drops in temperature or extremely cold surroundings. Additionally, these tubes maintain their exceptional corrosion resistance in low-temperature operations, particularly in chloride-rich or aggressive media.

In summary, Super Duplex heat exchanger tubes offer consistent performance, reliability, and longevity in both extremely hot and cold conditions, making them a top choice for critical thermal and corrosive applications.

SDSS heat transfer tube manufacturer in India

How are SDSS heat transfer tube tested for quality and performance?

SDSS heat transfer tube undergoes various tests to assess their quality and performance. They are visually inspected for any visible defects such as cracks, or improper dimensions.

We are SDSS heat transfer tube supplier in Mumbai, our samples from the SDSS evaporator tubing are analyzed using techniques such as OES or XRF to determine the chemical composition. Manufacturers conduct various mechanical tests to evaluate the strength and ductility of the DSS tubes.

To assure their quality and performance, super duplex boiler tubes are put through a variety of quality control tests

Super duplex finned tubes

SDSS super heater tube

Super duplex steel evaporator tubing

What is the difference between duplex and super duplex evaporator tubing?

The main difference between a duplex and a SDSS boiler tube lies in their composition and corrosion resistance capabilities. As compared to duplex stainless steel, SDSS usually offers better resistance to corrosion

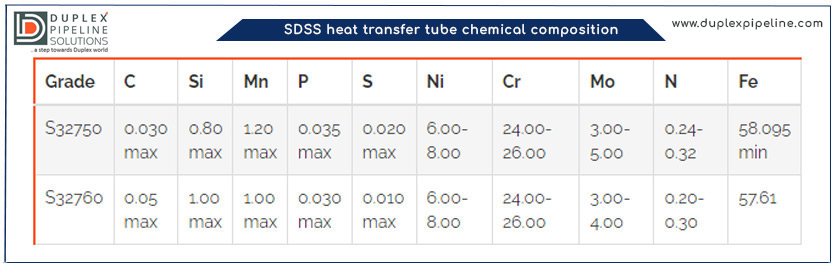

SDSS offers even higher corrosion resistance and strength compared to DSS. These SDSS tubes exhibit a higher concentration of chromium between 24% to 26% along with increased levels of molybdenum, and nitrogen.

Check with us benefits of using super duplex stainless steel reheater tubes and SDSS superheater tubes in various industries

We are high quality super duplex heat exchanger tubes manufacturer in India, to check our inventory contact us

For more information about possible sizes, view the datasheet for Super duplex steel double tube condenser.

Super duplex tube and fin condenser

- Size:5.0 to 1219.02mm

- End: Plain End, Beveled End

- Surface finish: Annealed & pickled

Super duplex stainless steel shell tube

- Wall thickness:

- Type: ERW/ Seamless /EFW

- Form: hollow, round, straight

Super duplex steel boiler tube

- Application: chemical

- Length: Single random, double random pipe

- Temp: 482°F (250°C)

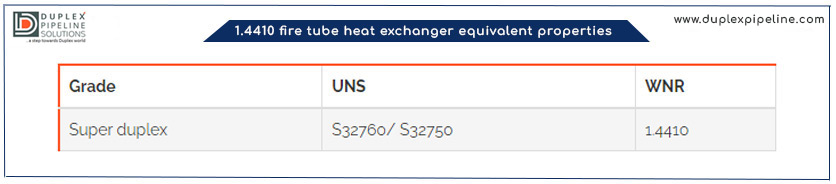

View wnr 1.4410 fire tube heat exchanger’s chemical and equivalent properties here

SDSS double-tube condensers offer excellent mechanical properties and corrosion resistance. These reheater tubes can be used in any hot area without any problems, or difficulties.

The SDSS superheater tubes have good thermal conductivity, enabling efficient heat transfer within the reheater tubes. The reheater tubes need this property for maintaining optimal temperature levels in high-pressure steam areas.

Super duplex stainless steel reheater tubes exhibit exceptional resistance to corrosion. This makes the reheater tubes highly suitable for environments with corrosive gases, liquids, or any such material.

SDSS heater tubes also possess high tensile strength and excellent mechanical properties. This strength ensures the reheater tubes can handle the stresses and strains associated with superheating processes without deformation or failure.

The lifespan of a Wnr 1.4410 fire tube heat exchanger can vary depending on several factors. The longevity and durability of SDSS can be attributed to its excellent corrosion resistance strength.

In general, well-designed and properly maintained super duplex steel boiler tubes can have a long lifespan. With appropriate care and maintenance, these boiler tubes can typically last for several decades