ASTM A789 UNS S31803 seamless tube

Annealed and Pickled finish involves a heat treatment process known as annealing, followed by pickling to remove oxide scales from the tube. Manufacturers give the tubes a bright-annealed finish by subjecting the tube to a controlled atmosphere annealing process followed by pickling.

Mechanical polishing involves the use of abrasive materials and tools to remove surface imperfections of the ASTM A789 UNS S31803 seamless tube. Manufacturers employ the electropolishing process to remove surface irregularities and contaminants and give the tubes a smooth, bright finish

S31803 welded tube manufacturer in India

ASTM A789 UNS S31803 tubes have a high strength-to-weight ratio, making them suitable for applications requiring resistance to high pressures. The duplex stainless steel composition consisting of both austenite and ferrite phases provides the tubes excellent mechanical properties.

UNS S31803 hydraulic tubing exhibits good fatigue resistance and can sturdily withstand cyclic loading caused by pressure fluctuations. These tubes can endure repeated stress cycles without developing cracks or failure and maintain their integrity under high-pressure conditions

Supplier of UNS S31803 hydraulic tubing in form of condenser tubes, oval tube and rectangular tubing, check online inventory

SA 789 UNS S31803 heat exchanger tubes

ASTM A789 welded tube

UNS S31803 hydraulic tube

First, the manufacturers heat the raw material in a controlled environment for further processing and then pierce it to create a central hole. The manufacturer then subjects the pierced billet to hot extrusion and then employs heat-treatment processes such as annealing.

The annealed SA 789 UNS S31803 heat exchanger tubes may go through cold working processes such as drawing or “pilgering”. Lastly, the NFA 49-217 UNS S31803 instrumentation tubing undergoes various surface treatment processes to achieve specific project demands and requirements.

Check sizes chart and length in meter of SA789 S31803 tubing here

ASTM A789 UNS S31803 annealed tubes available in 1.5 Od for the aerospace industry, contact us

ASME SA 789 UNS S31803 erw tube

- Thickness: 0.89 – 5.00 mm

- Applications: Petrochemical & Refinery

- Surface finish: pickled

ASTM A789 UNS S31803 instrumentation tubing

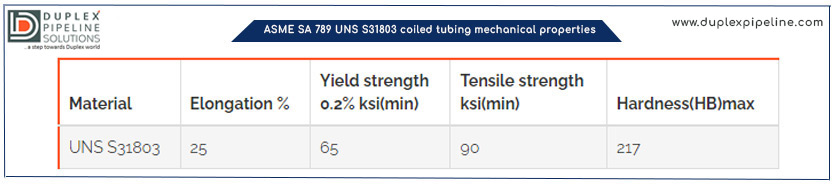

- Brinell hardness: 290 (Rc31)

- Tensile strength: 620 MPa

- Packaging type: box

ASME SA 789 annealed tubes

- Form: hydraulic, rectangular, square

- Size: 1/2 to 24″

- Length: 0.51mm – 25.4mm

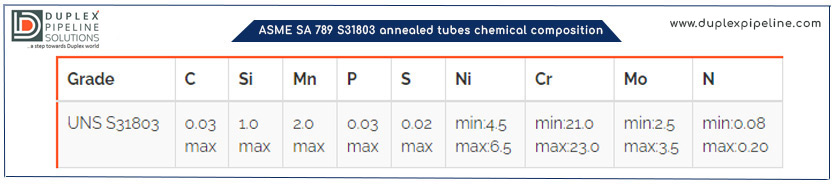

To know the minimum yield strength and tensile strength of ASME SA 789 UNS S31803 coiled tubing check our specification table

ASTM A789 welded tube exhibits excellent corrosion resistance particularly in marine environments. It resists general corrosion, pitting, and crevice corrosion caused by chloride ions, making it well-suited for applications in saltwater and other corrosive marine environments.

Stress corrosion cracking is a significant concern in marine environments due to the presence of chlorides and other corrosive elements. ASME SA 789 annealed tubes exhibit good resistance to stress corrosion cracking providing added reliability and longevity in marine applications.

EN 10216-5 UNS S31803 erw tube is widely utilized in power generation facilities. This entails applications such as fossil fuel power plants, nuclear power plants, and renewable energy installations. These steel pipes are employed in applications such as heat exchangers, condensers, and boiler tubes in power units.

ASME SA 789 UNS S31803 coiled tubing undergoes visual inspection and dimensional inspection methods. The dimensional inspection involves verifying the dimensions of the tubing while visual inspection checks the surface for any visible defects.