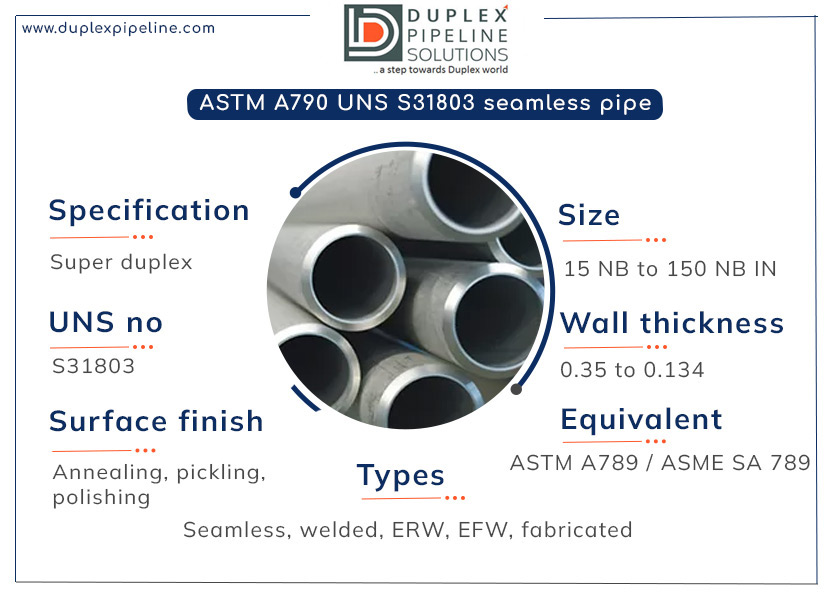

ASTM A790 UNS S31803 seamless pipe

These pipes have a special balanced microstructure consisting of both austenite and ferrite phases. This unique double microstructure of the pipes provides better resistance to various corrosive agents including acids and chlorides

ASTM A790 UNS S31803 seamless pipe exhibits higher strength as compared to regular steel products. This high strength allows the pipes to sturdily withstand higher pressures and loads without any deformation or failure.

S31803 welded pipe supplier in India

SA 815 UNS S31803 welded pipe generally exhibits good toughness and impact resistance even at sub-zero temperatures. The specific impact resistance of these pipes at low temperatures can be attributed to many factors such as duplex microstructure and phase transformation.

SA 815 UNS S31803 exhaust pipe has a duplex microstructure consisting of approximately equal amounts of ferrite and austenite phases. This balanced microstructure of the pipes contributes to their enhanced toughness and impact resistance, even in cryogenic conditions.

Ferrite is inherently more resistant to brittle fracture which is especially important at low temperatures when materials tend to become more brittle. This characteristic enhances the impact resistance of welded pipes in low-temperature environments.

We can supply UNS S31803 pipe at reasonable price in Mumbai

SA 815 UNS S31803 exhaust pipe

Duplex UNS S31803 welded pipe

ASTM A815 UNS S31803 efw pipe

Manufacturers must properly clean the surfaces of the pipes to remove any contaminants to achieve high-quality welds. The welding method for the duplex UNS S31803 pipe must be selected based on the thickness of the pipes, and application requirements. Welding consumables must be selected wisely to maintain the corrosion resistance and mechanical properties of ASTM A815 erw pipe

Know more about SA 815 UNS S31803 schedule 40 pipe, read specifications

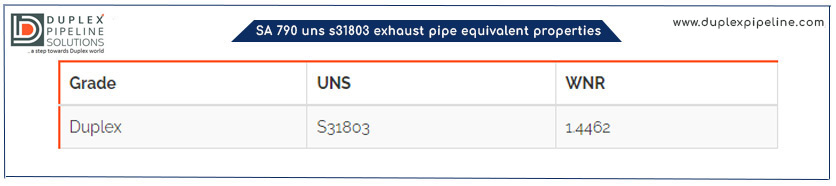

Are you looking for SA 790 UNS S31803 exhaust pipe equivalent chart, find here

SA 815 UNS S31803 schedule 40 pipe

- Size: 6 – 710mm

- Wall thickness: 1.0mm-20mm

- Application: chemical, pulp

UNS S31803 erw pipe

- O.D. x I.D. 1/16″. x 0.005″

- Shape: round, square, hex

- Yield strength: psi – 80000

ASTM A815 square pipe

Temperature range: 1100°C to 1250°C

- Tensile strength: 800 MPa

- Coating: annealed

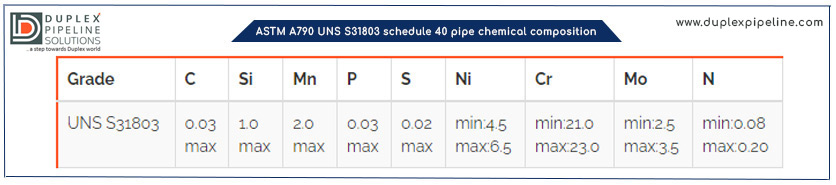

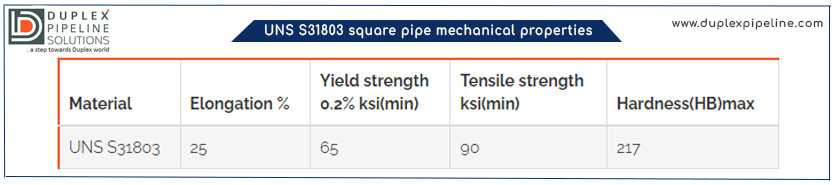

Get online duplex UNS S31803 square pipe chemical composition and mechanical properties

The heat treatment process for ASTM A815 UNS S31803 schedule 40 pipe which is a type of duplex stainless steel pipe typically involves solution annealing. The purpose of the heat treatment is to restore the material’s microstructure and mechanical properties, eliminate any residual stresses, and improve corrosion resistance.

In solution annealing, the pipe is heated to a temperature within the range of 1020°C to 1100°C (1868°F to 2012°F) and held at that temperature for a specified period of time. The duration of the annealing process depends on the thickness of the pipe and can vary typically ranging from 30 minutes to a few hours.

SA 815 UNS S31803 efw pipe is employed in the production of chemical processing equipment such as reactors, columns, heat exchangers. Petrochemical plants also employ these steel pipes for different applications including the transportation of petroleum products and processing of hydrocarbons.

The outside dimensions of the UNS S31803 square pipe are ±0.5% or ±1% of the nominal size and the length is ±3 mm or ±6 mm. These pipes undergo a mill finish to get a slightly rough appearance or the pickled finish process to achieve a uniform surface.