Application of duplex stainless steel

Applications and Advantages of Duplex Stainless Steel in the Oil and Gas Industry

Duplex stainless steel has gained significant popularity in the oil & gas industry due to its excellent properties. Here, we have listed some of the top duplex stainless steel applications:

- Offshore Platforms: Duplex ss is extensively used in the construction of offshore platforms. Its high strength & corrosion resistance is ideal for withstanding the harsh marine environment. This will include exposure to saltwater, high-pressure conditions, and corrosive chemicals.

- Subsea Equipment: Subsea pipelines, risers & manifolds face demanding conditions like high pressures & corrosive environments. Duplex ss offers excellent resistance to pitting, crevice corrosion & stress corrosion cracking. Thus, duplex stainless steel for seawater application is considered to be a great choice.

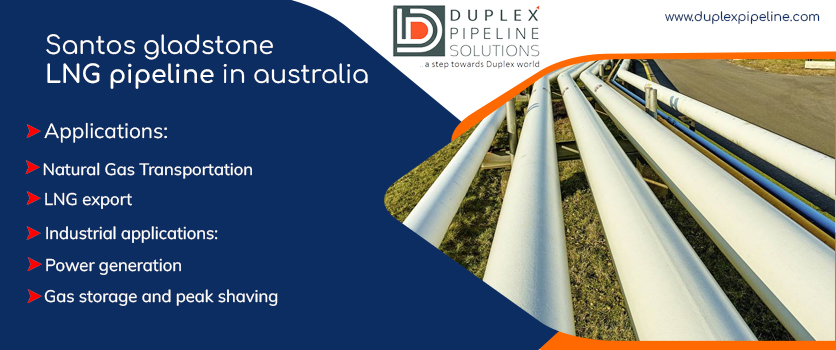

- Oil and Gas Pipelines: Duplex ss is used in both onshore and offshore oil & gas pipelines. Its high strength enables the transportation of oil & gas over long distances. Its resistance to corrosion helps mitigate the risk of pipeline failures caused by internal & external corrosion. Thus, they ensure the reliability of pipeline infrastructure.

- Refineries: The steel is utilized in various refinery applications like distillation columns, heat exchangers & storage tanks. Its resistance to stress corrosion cracking & excellent mechanical properties make it suitable for handling aggressive process fluids and high-temperature environments.

- Weldability and Fabrication: They exhibit good weldability, simplifying the fabrication process and reducing production costs. This allows for the efficient construction of complex structures and equipment in the oil & gas industry, ensuring reliable and cost-effective manufacturing.

The advantages of duplex ss in the oil & gas industry are:

- They show superior resistance to corrosion, especially in chloride-rich environments. They also show resistance to pitting, crevice corrosion & stress corrosion cracking which enhances the durability & reliability of equipment.

- They possess higher strength compared to conventional austenitic ss. Thus, they are used in applications requiring high load-bearing capacity like offshore platforms & subsea equipment.

- It is cost savings due to its high strength, corrosion resistance & excellent lifetime performance. It reduces maintenance requirements, downtime & replacement costs associated with equipment failures caused by corrosion.

- The steel exhibits excellent fatigue resistance, allowing it to withstand cyclic loading & vibrations. This is crucial where structures & equipment are subjected to fluctuating mechanical stresses

- The risk of equipment failure and subsequent environmental hazards can be minimized using duplex ss. Its superior corrosion resistance properties and mechanical strength contribute to enhanced operational safety and reduced environmental impact in the oil & gas industry.

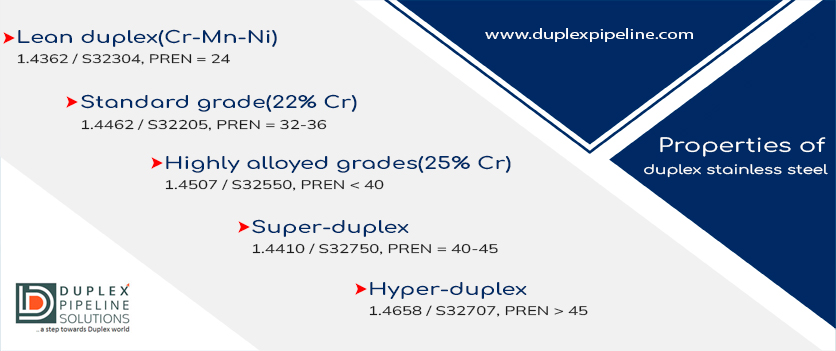

What are the unique properties of duplex stainless steel?

The application of duplex stainless steel is due to the unique properties they possess:

- It has a dual microstructure that roughly consists of equal proportions of austenite & ferrite phases.

- This combination gives duplex ss its exceptional properties like high strength, excellent corrosion resistance, good weldability & resistance to stress corrosion cracking.

- Its ability to withstand harsh environments like chloride-rich & high-temperature conditions makes it ideal for the oil & gas industry. In other words, it is ideal for services where reliability and durability are paramount

- They are also known for cost efficiency by reducing maintenance requirements and extending equipment lifespan.

Duplex steel fittings

Duplex elbow

Duplex steel tee

What is the duplex steel corrosion rate in harsh environments? Know more about its strength and durability

Duplex stainless steel exhibits a low corrosion rate in harsh environments due to its excellent resistance to pitting & crevice corrosion. It outperforms other ss grades in chloride-rich & aggressive media.

The dual microstructure of duplex ss contributes to its superior strength, allowing it to withstand high mechanical loads & pressures. Its high yield strength provides structural integrity, while its ductility prevents brittle fracture.

The steel also demonstrates exceptional durability, with resistance to stress corrosion cracking & fatigue. This ensures long-term performance in demanding applications. These properties make duplex ss a reliable choice for industries like oil & gas, where corrosion resistance, strength and durability are critical.

How is it cost-effective compared to other materials?

- Duplex steel has high strength which allows the use of thinner sections, reducing material costs. This is without compromising structural integrity.

- Its excellent corrosion resistance minimizes maintenance requirements, reducing downtime and associated costs.

- Duplex stainless steel has high durability and resistance to corrosion, pitting & stress corrosion cracking. These properties also contribute to extended equipment lifespan, reducing replacement and repair costs.

- It has good weldability which simplifies fabrication processes and reduces labor & production costs

Check few case studies and real-world examples about use of duplex stainless steel in below applications

Aditya, a passionate blogger and experienced writer shares his insight about the metal and piping industry. He has a keen eye for industry trends and a knack for simplifying complex concepts. Aditya’s blog provides readers with valuable insights and guidance in making informed decisions for their pipeline projects