Duplex pipe

What is Duplex pipe?

A duplex pipe is in fact a type of stainless steel pipe that is manufactured from duplex stainless steel. The steel is defined by its specific composition, which is made up of roughly equal amounts of two phases: austenite and ferrite. The advanced structural properties of duplex stainless steel give the pipe its advanced strength, which is roughly double that of regular stainless steel. Moreover, the advanced construction gives the pipe its advanced resistance to corrosion, which makes it especially well-suited for use in hostile environments that are filled with chlorides.

Duplex pipes are employed in many different industries,some of which include but are in no way limited to oil and gas exploration, chemical processing plants, desalination plants, and marine construction. The pipes are especially prized for their advanced resistance to stress corrosion cracking, pitting, and crevice corrosion, which can be problematic in most industrial environments. Two of the most widely used and applied grades of duplex stainless steel are 2205 and 2507. The benefits provided by duplex pipes are not only long-term performance and reliability but also lower maintenance and overall cost-effectiveness, which makes them a very desirable option for many different applications.

Applications of Duplex Pipes:-

🛢️Oil & Gas – Offshore and subsea pipelines, refineries, LNG processing.

🏭 Chemical & Petrochemical – Corrosive fluid transport, heat exchangers, storage tanks.

🚢Marine & Shipbuilding – Seawater piping, ballast systems, exhaust scrubbers.

💧Desalination & Water Treatment – Reverse osmosis plants, brine processing, wastewater treatment.

⚡Power Generation – Heat exchangers, steam pipelines, boiler systems.

Why To Choose Our Duplex Pipes?

✅ Stringent Quality Control & Compliance

✅ Competitive Pricing & Fast Delivery

✅ Customization Available for Specific Project Needs

Which method is best to produce duplex steel seamless pipe?

Duplex pipe production is typically done through the use of the extrusion method and the rotary piercing method. Forced extrusion is used to produce DSS seamless pipe form by squeezing a steel hot billet through a die.

Conversely, rotary piercing entails piercing with a pointed mandrel a hot billet. Prior to the creation of the DSS welded pipe, the billet is extended.

Duplex steel seamless pipe supplier in India

What are the advantages of using duplex welded pipe in corrosive environments?

A DSS pipe has several advantages where corrosion occurs. The DSS pipes utilize both the austenitic and ferritic stainless steels.

DSS pipes and tubing are highly resistant to various forms of corrosion such as crevice corrosion, pitting, and stress corrosion cracking. This makes a DSS schedule 40 pipe a very suitable choice for high-chloride or severe chemical conditions.

We are top 7 duplex stainless steel seamless pipe stockist in India, our duplex stainless schedule 40 pipe are manufactured using advanced techniques

Duplex stainless steel pipes

Duplex Welded pipe

Duplex seamless pipe

Top 6 things you should remember while buying duplex stainless steel pipe

- Determine the unique qualities and attributes that each grade possesses

- Evaluate the corrosion resistance of the DSS round pipe

- Verify that the DSS ERW pipes meet quality standards

- Consider the required dimensions, including pipe diameter, wall thickness, and length

- Choose a reputable supplier who deliverers quality DSS pipes

- Don’t stress the price, emphasize the value that DSS pipes provide

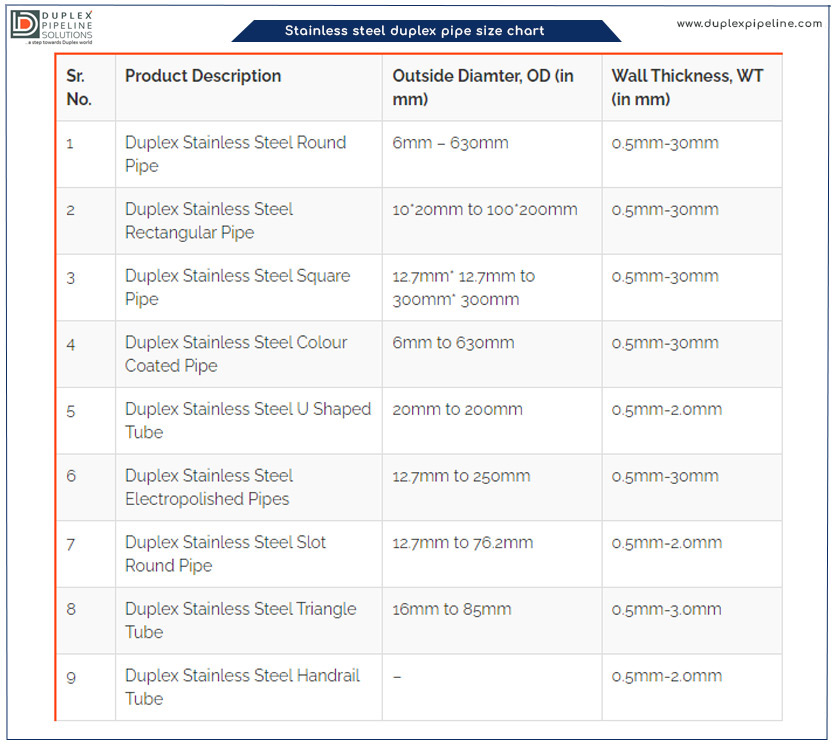

We supply duplex steel pipe for various industries, check sizes and wall thicknesses of our stainless steel duplex ERW pipes

Table of Content

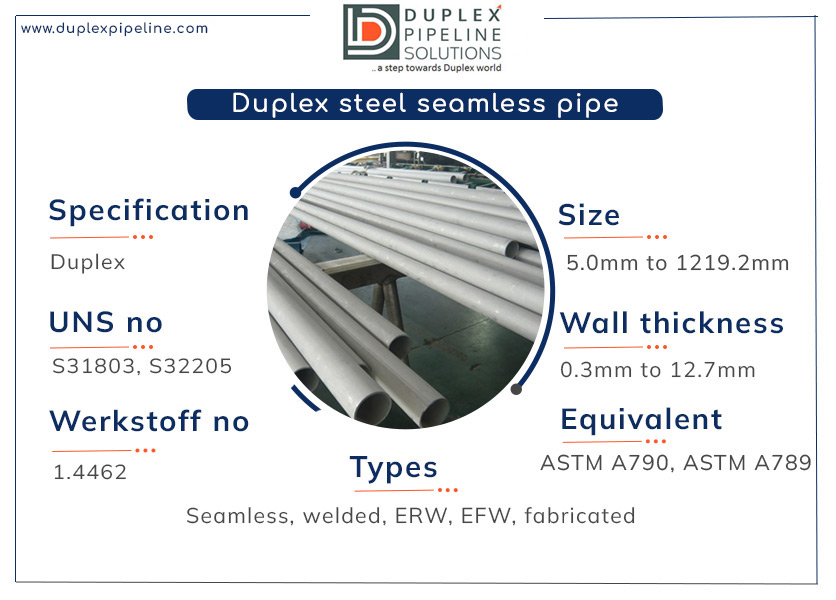

- Specification of duplex steel seamless pipe

- Types of duplex stainless pipe

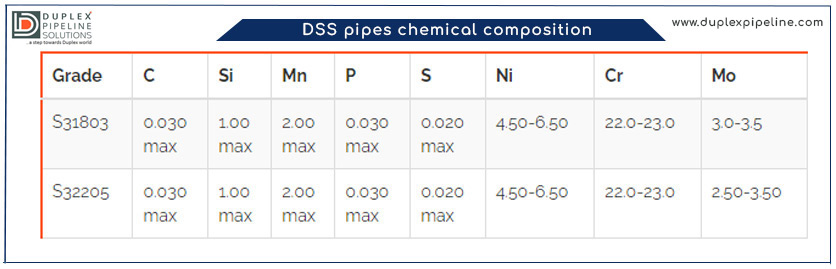

- Chemical composition of DSS pipe

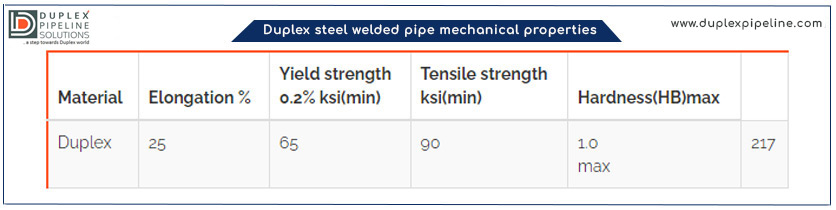

- Mechanical properties of duplex steel welded pipe

- Size chart of stainless steel duplex pipe

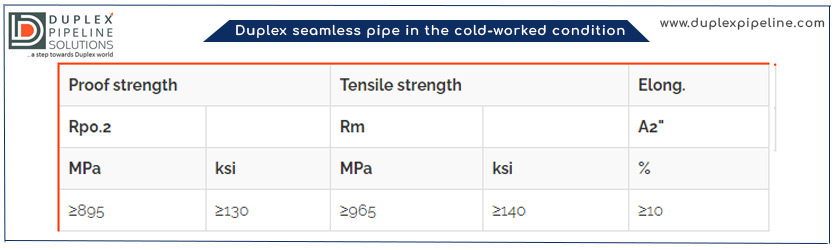

- Cold worked condition of duplex seamless pipe

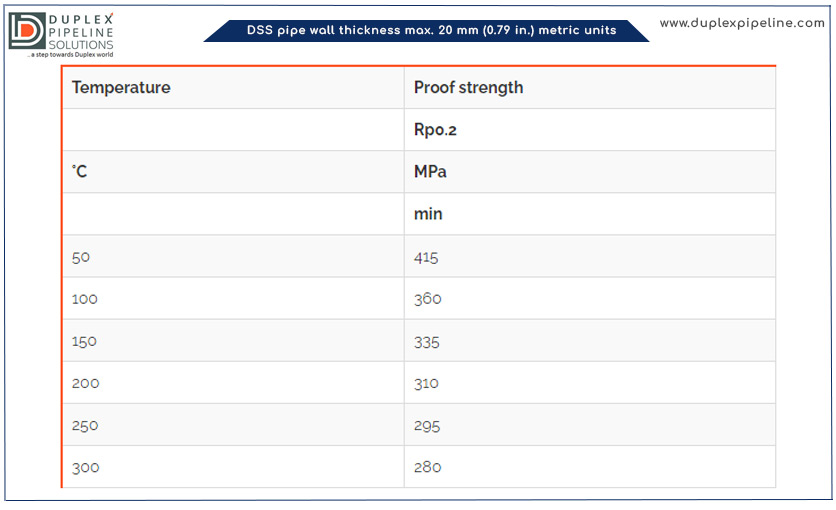

- Wall thickness of DSS pipes (metric-units)

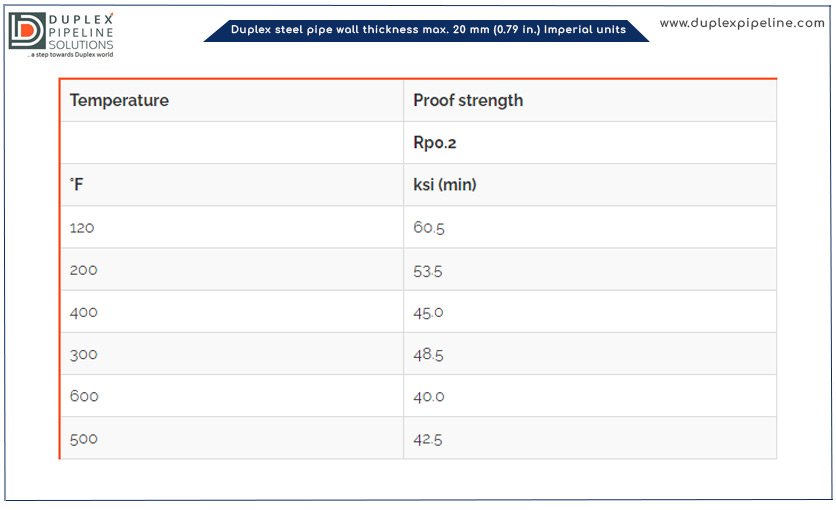

- Wall thickness of duplex steel pipes (imperial-units)

We are top, high quality duplex pipe supplier in India

Looking for duplex stainless steel pipe supplier in India for urgent delivery? check latest online price list

DSS ERW pipe

- OD: 5.0mm – 203.2mm

- Wall thickness: 0.5mm to 20mm

- Length: 1/8″ – 3 1/2″

Stainless steel duplex pipe

- Manufacturing process: extrusion process

- Hardness: 270 Max HB

- Shape: round, square, rectangular

DSS square pipe

- Application: petrochemical

- Tensile strength: 620 MPa

- Yield strength: 450 MPa

View duplex round pipe chemical composition and equivalent specification

Non-destructive testing (NDT) methods are used by manufacturers to detect issues in duplex pipes. The following are some of the most regularly used NDT techniques for assessing DSS suppliers in India:

- Visual Inspection (VI)

- Magnetic Particle Inspection (MPI)

- Liquid Penetrant Testing (LPT)

- Radiographic Testing (RT)

Depending on the unique requirements of the DSS pipes, these NDT procedures can be employed singly or in combination

Project engineers use DSS pipes in various industries due to their excellent combination of corrosion resistance, strength, and durability. These DSS tubing and pipes serve a variety of functions in oil refineries.

A DSS square pipe is frequently used in chemical and petrochemical industries where resistance to strong chemicals is critical. These DSS pipes are used in water and wastewater treatment plants for transporting and distributing treated water.

🧱 1. High Strength

About twice as strong as standard stainless steels like 304/316 — allows for thinner, lighter, and more cost-effective designs.

🛡️ 2. Excellent Corrosion Resistance

Tough against pitting, crevice corrosion, and stress corrosion cracking — perfect for harsh, salty, or chemical-heavy environments.

♻️ 3. Great Fatigue & Impact Resistance

Handles shocks and repeated stress well, even in cold conditions — better than most austenitic steels.

🌡️ 4. Moderate Heat Resistance

Works fine up to 250–300°C. Higher temps might cause brittleness from unwanted phase formation.

⚖️ 5. Balanced Microstructure

Roughly 50/50 austenite and ferrite — giving it a strong mix of toughness, ductility, and corrosion resistance.

⚙️ 6. Good Weldability (with care)

Welds well with standard methods, as long as you control heat, use the right filler (like ER2209), and manage temperatures to protect the structure.

🧪 7. High Erosion & Abrasion Resistance

Great for flow-heavy or particle-abrasive environments where wear is a concern.

Here are the list of recommended filler metals:-

- TIG/GTAW

- MIG/GMAW

- ISO 14343 S 22 9 3 N L

- AWS A5.9 ER2209

- MMA welding

- SMAW welding

- ISO 3581 E 22 9 3 N L R

- AWS A5.4 E2209-17

- ISO 3581 E 22 9 3 N L B

- AWS A5.4 E2209-15

- ISO 14343 S 22 9 3 N L

- AWS A5.9 ER2209 welding wire

- ER2209 strip electrodes