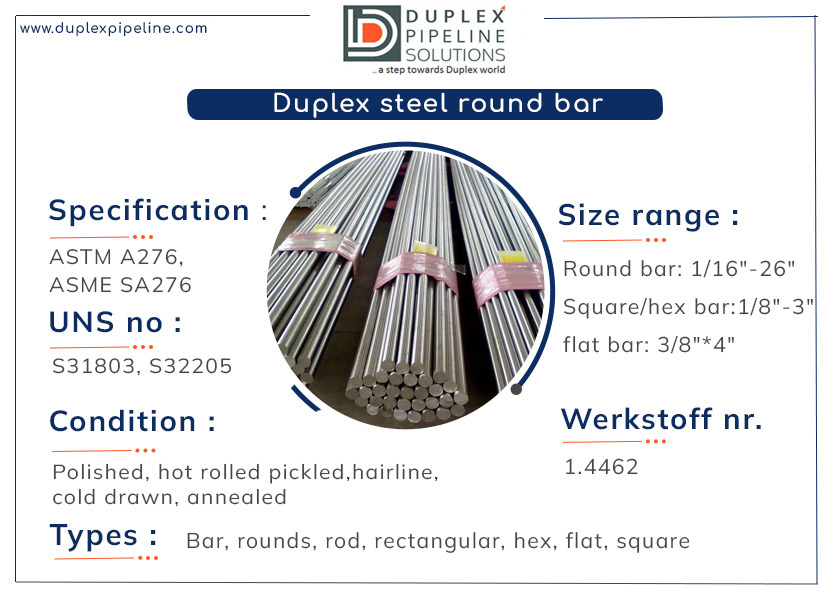

Duplex round bar

These round bars exhibit exceptional corrosion resistance, particularly in aggressive environments such as chloride-containing solutions. The round bars offer improved fatigue resistance compared to austenitic stainless steel.

The DSS round bar has good weldability and can be easily used for fabrication and joining. Their superior mechanical properties and corrosion resistance can result in cost savings over the product’s lifetime.

Duplex stainless steel square bar manufacturer in India

Duplex steel flat bar is available in a variety of thicknesses ranging from millimeters to inches. The thickness depends on the desired application and the manufacturing capabilities of the ASTM A276 DSS round bar suppliers in India. A DSS bright bar is usually available in thicknesses ranging from 3 mm (0.12 inches) to 50 mm (1.97 inches).

We provide best quality of duplex steel rounds and DSS hex bars, to check our inventory visit us

Duplex rounds

DSS square bar

Duplex stainless steel bar

The manufacturing process of the A479 DSS square bar plays an important role in ensuring material integrity. Proper control of parameters like temperature is essential to maintain the desired microstructure and mechanical properties of the DSS.

Manufacturers precisely control the forming, shaping, and finishing processes to achieve the desired square shape of the bar. Hot rolling and forging processes can improve the strength and grain structure of the bar material.

We use advanced polishing and finishing techniques to achieve a high-quality surface finish on our duplex steel flat bar

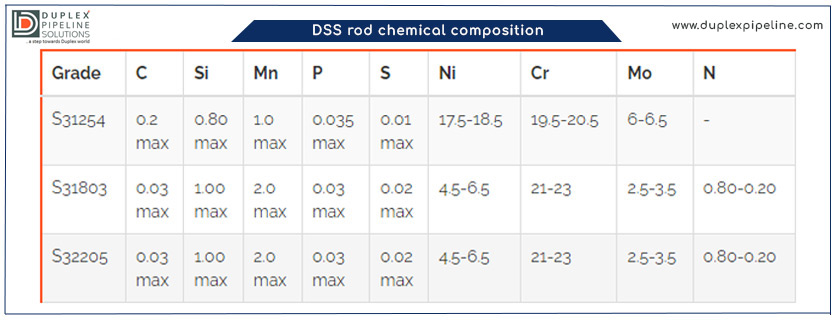

We are best quality duplex stainless steel rod manufacturer in India

Our duplex rod offers high resistance to a variety of corrosive situations because of its special composition

Duplex bar

- Size: 3.0 – 50.8 mm

- Finish: bright, polish & black

- Length: 1 – 2000mm

Duplex steel rounds

- Form: round, square, hex, flat

- Application: off-shore oil drilling

- Testing: PMI

Duplex ss round bar

- Melting point: 1400 – 1455°C

- Tolerance: 2.5%

- Diameter: 10 mm – 200 mm

To view the technical specifications of duplex steel round bar, please visit our website for detailed information

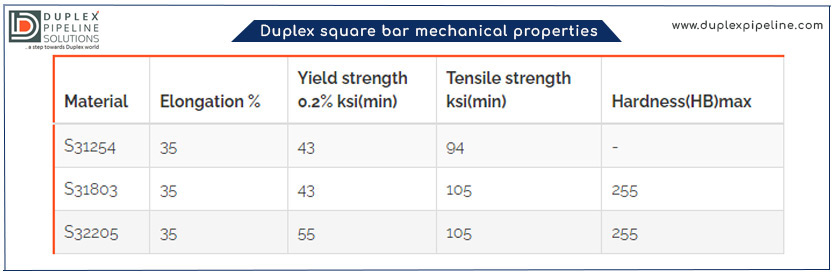

We are duplex round bar supplier in India, The tensile strength of our DSS hex bar can vary depending on the specific alloy composition, heat treatment, and manufacturing. Manufacturers maintain the tensile strength of DSS bars in the range of 620 MPa or 90 ksi to 900 MPa 130 ksi, or even higher.

NOTE – the actual tensile strength of the DSS bar can vary based on the specific grade of DSS and any additional heat treatment.

A hot rolled DSS rod has a characteristic mill scale and a rougher surface finish. Cold-drawn processes usually impart a smoother and more uniform surface finish to the rods.

Centerless grinding is a precision grinding process used by manufacturers to achieve a high-quality surface finish on DSS rods. Polished rods undergo mechanical or chemical polishing processes to get a smooth, reflective, and aesthetically appealing surface.

A EN 10088-3 DSS bar generally tends to be priced higher than other types of steel. This is because DSS contain a higher amount of alloying elements such as chromium, nickel, and nitrogen, unlike standard SS.

These steel bright bars undergo specific manufacturing processes to achieve the desired bright and smooth surface finish. These additional processing steps and the associated equipment and expertise required contribute to the higher cost of the bars.