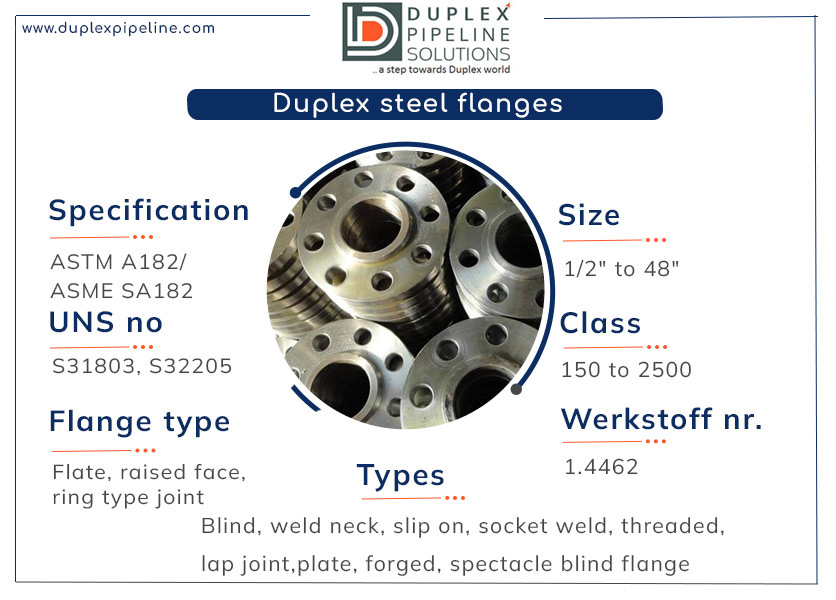

Duplex steel flanges

Duplex steel flanges are flanges made of DSS material that exhibits excellent resistance to various types of corrosion. It is named duplex as unlike other flanges it has a two microstructure that entails an equal composition of austenite and ferrite.

DSS flanges display higher strength as compared to austenitic stainless steel products. These stainless steel flanges generally have good weldability and allow for easy fabrication and installation operations.

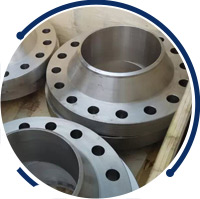

DSS slip on / weld neck flange manufacturer in India

DSS manufacturers typically utilize various microscopy techniques such as optical microscopy and scanning electron microscopy or SEM to examine the heat-treated flanges. The microstructural analysis process employed in the DSS flange enables the manufacturers to evaluate the phase balance, grain structure, and the presence of any detrimental phases.

Steel manufacturers employ metallographic processes such as optical microscopy and electron microscopy to check the grain structure of DSS flanges. Hardness tests such as Rockwell hardness is usually conducted during the manufacturing process to measure the DSS resistance capacities to indentation.

We are duplex steel forged flanges supplier in Mumbai, we employ the best thermal processing method, contact us for more details

Duplex steel reducing flanges

DSS weld neck flange

Duplex steel threaded flanges

DSS reducing flanges exhibit excellent corrosion resistance, particularly in aggressive environments containing chloride solutions. This resistance lowers the risk of material degradation and extends the service life of the DSS slip-on flange.

A DSS weld neck flange exhibits excellent yield strength, tensile strength, and fatigue strength, thereby allowing for the use of thinner sections. DSS flange may have a higher initial cost as compared to some other steel materials but it offers amazing long-term cost savings.

Our duplex stainless steel flanges come in various sizes and dimensions to meet the specific requirements of your project

We are top duplex flange manufacturer in India, check our stock here

Our duplex blind flange undergo rigorous testing to ensure their corrosion resistance properties meet the highest industry standards

Duplex slip on flanges

- Size: 1/2″ – 48″

- Application: airpspece industry

- Yield Strength: 290 MPa

Duplex steel socket weld flanges

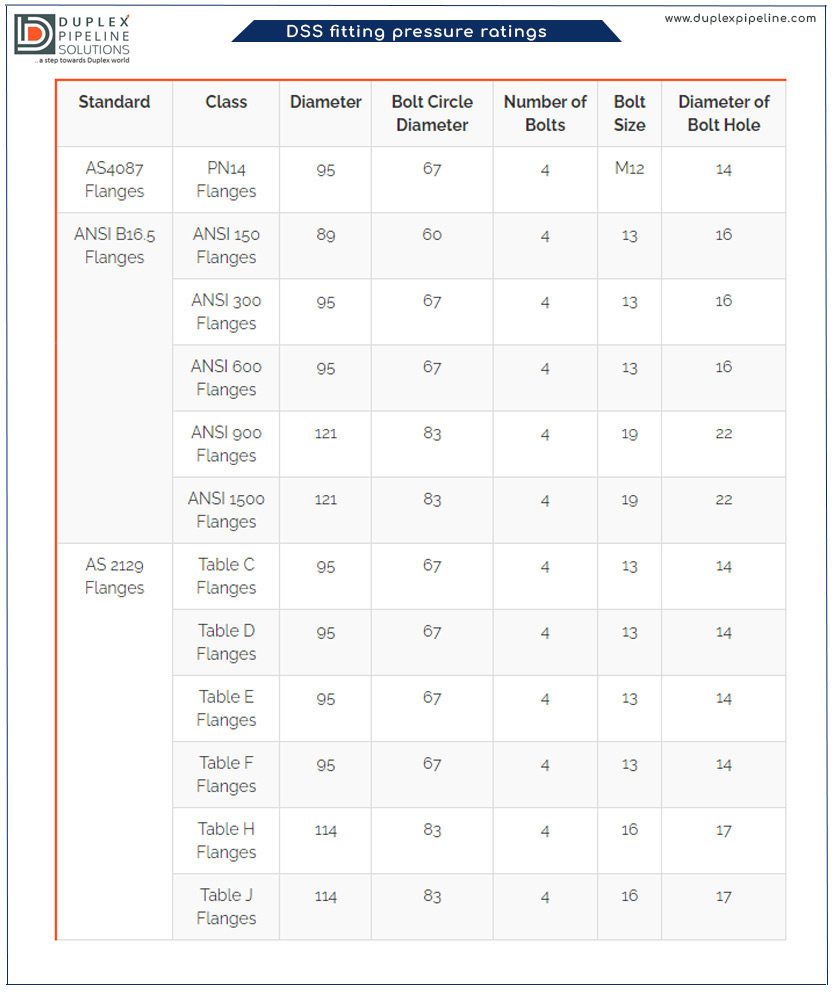

- Pressure class: 150 – 2500

- Type: blind,slip on, weld neck

- Face type: Rtj, RF, FF, T&G

Duplex blind flanges

- Coating: anti-rust painting

- Tensile strength: 415 MPa

- Elongation: 50mm

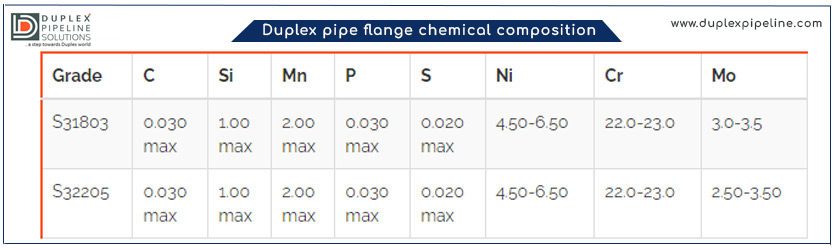

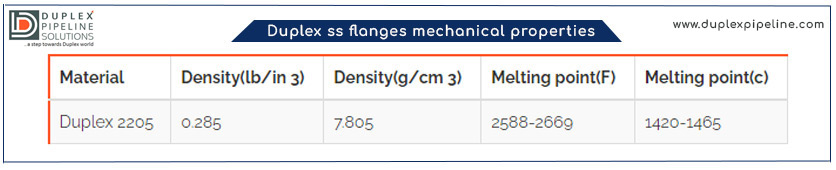

For detailed information on the chemical and mechanical properties of our duplex steel orifice flange, please view our product datasheets

The diameter or nominal pipe size NPS of a duplex blind flange has a direct impact on its weight and cost. Unlike small-diameter flanges, large-diameter flanges involve more material during the manufacturing process which hikes up its costs.

The thickness of DSS threaded flanges impacts their overall weight and cost. Thicker flanges are heavier and require more material during manufacturing, thereby leading to higher costs.

The special alloy composition of the DSS employed in slip-on flanges plays a significant role in determining their corrosion resistance. Molybdenum can enhance the corrosion resistance of DSS products, especially in chloride and acid containing environments

The corrosive environment in which the slip-on flanges will be used significantly impacts their corrosion resistance. Factors such as temperature, pH level, chloride concentration, and other aggressive chemicals affect the corrosion of duplex steel socket weld flanges.

DSS ring joint flanges are typically magnetic due to their composition which includes a significant amount of ferrite phase. DSS are duplex in nature, consisting of both ferrite and austenite phases.

The magnetism of the DSS RTJ flanges can vary based on the specific composition and heat treatment process employed on the DSS. Some grades of DSS exhibit a higher ferrite content and therefore show stronger magnetic properties than other SS grades.