Duplex Tube

What is Duplex Tube?

A duplex tube is a straight product manufactured from duplex stainless steel, a special category of stainless steel known for its dual-phase microstructure. This microstructure is composed of approximately equal parts of austenite (a face-centered cubic crystal structure) and ferrite (a body-centered cubic crystal structure).This dual-phase nature is what gives the material its name: “duplex.”

Duplex tubes are engineered to offer a balanced combination of mechanical strength, corrosion resistance, and durability, making them highly satisfactory for demanding industrial environments.

What are the features and applications of duplex tubing?

🔧 Features of Duplex Tubing:-

- High Strength

Duplex stainless steels possess approximately double the tensile strength of conventional austenitic or ferritic stainless steels.” - Excellent Corrosion Resistance

Especially resistant to chloride stress corrosion cracking, pitting, and crevice corrosion—making it ideal for aggressive environments.

Improved Toughness

Better toughness than ferritic grades, especially in low temperatures. - High Fatigue Resistance

Can withstand cyclic loading, useful in dynamic environments like offshore drilling. - Cost-Effective

Despite being more expensive than carbon steel, its longer lifespan and lower maintenance make it more economical over time. - Good Weldability

More weldable than ferritic stainless steels but requires proper heat input to maintain balance between ferrite and austenite.

🛠 Applications of Duplex Tubing:

- Oil & Gas: Subsea pipelines, wellheads, heat exchangers

- Desalination Plants: Handles chloride-rich seawater

- Chemical Processing: Reactors, process piping, and pressure vessels

- Marine Industry: Offshore structures, boat shafts, and propellers

- Power Generation: Boilers, heat exchangers, and condensers

Pulp & Paper: Bleaching equipment, digesters

What makes our duplex tubes ideal for high-stress, corrosive environments?

Our duplex tubes are engineered to deliver exceptional performance where strength and corrosion resistance are critical. Made from a balanced mix of austenitic and ferritic stainless steel, they offer nearly double the strength of standard stainless steels—while maintaining excellent resistance to pitting, stress corrosion cracking, and crevice corrosion, especially in chloride-rich environments.

This makes them a trusted choice for demanding industries like oil & gas, chemical processing, marine, and desalination. We also ensure every tube meets strict quality standards and specifications, so you can count on long-term reliability even in the harshest conditions.

What are the advantages of using duplex tubes in industrial applications?

1-Exceptional Corrosion Resistance

- Pitting and crevice corrosion.

- Chloride stress corrosion cracking.

- General corrosion under acidic and salty conditions.

- Duplex tubes are optimum for marine, offshore, chemical, and desalination operations because of perennial corrosion threats.

2-Strength and Performance

- Duplex tubes have double the yield strength of standard austenitic stainless steels (e.g., 304 and 316).

- This allows for lighter walls, reducing material while decreasing cost with no performance loss.

- Excellent fatigue resistance, particularly under dynamic or high-pressure loading.

3-Prolonged Lifespan

- Duplex tubes are strong and corrosion-resistant, so they will endure longer in harsh industrial environments.

- Less maintenance and replacement reduce overall cost of ownership.

4-Cost Efficiency

- Duplex pipe might initially cost more to buy than carbon steel, yet its durability and ease of maintenance will pay dividends in the long run.

- Thin walls of tubes result in less material and shipping cost.

5-Good Weldability and Fabrication

- New duplex stainless steels are designed to weld with low risk of cracking.

- Adapts to different production methods including cutting, bending, and forming.

Duplex stainless steel welded tubing manufacturer in India

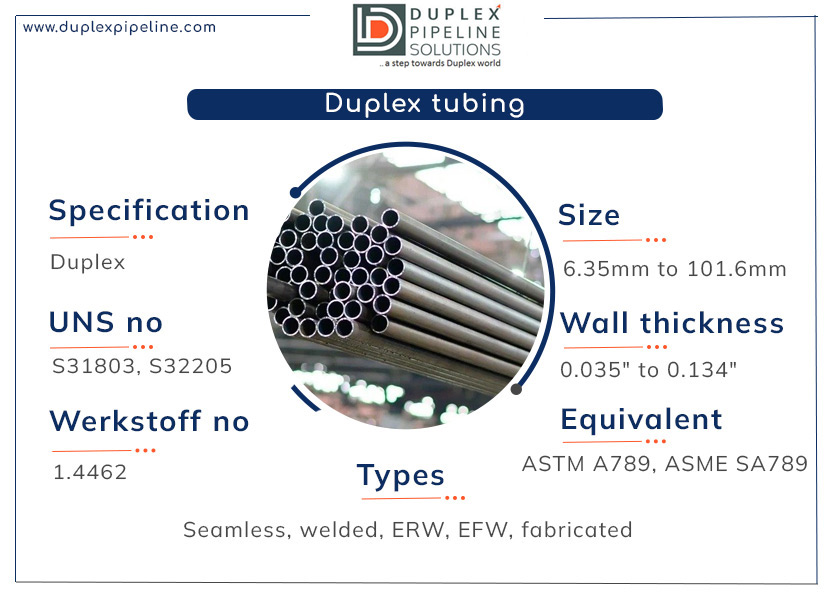

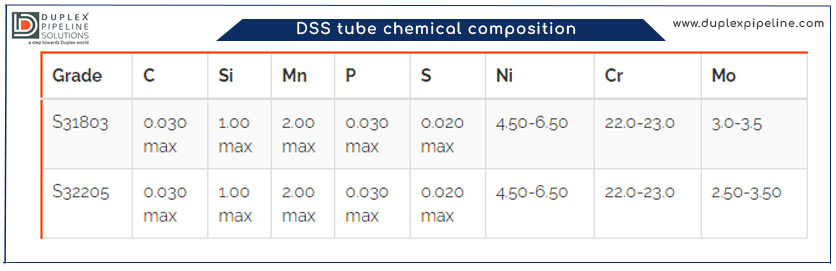

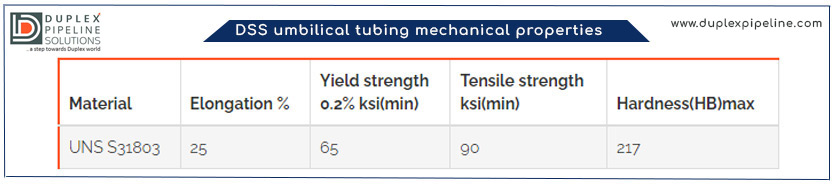

The most commonly used DSS grades for tubing are duplex 2205 (UNS S32205/S31803). 2507 (UNS S32750) and lean duplex (e.g., UNS S32304, S32003) are some other popular grades of DSS.

A DSS tube exhibits excellent corrosion resistance, especially in aggressive environments. These tubes also have higher strength compared to conventional austenitic stainless steel. A DSS hydraulic tubing consists of approximately equal amounts of austenite and ferrite phases.

Duplex pipeline offers a wide range of duplex seamless tubes which has excellent forming and welding characteristics

Duplex ss tube

Duplex steel welded tube

Duplex 2205 coiled tubing

Heating plays a vital role in refining the characteristics of a DSS seamless tube. By subjecting the tubes to controlled thermal cycles, their microstructure and mechanical properties are significantly enhanced.

One key process, solution annealing, improves corrosion resistance and toughness by dissolving chromium nitrides and carbides. This treatment ensures a well-balanced microstructure, enhancing the tube’s strength, durability, and overall performance in demanding environments.

We are India’s biggest duplex stainless steel tube supplier in Mumbai, check DSS welded tube chemical and mechanical properties

We are a leading duplex tube manufacturer in India, to check our stock visit us

To ensure that the DSS hydraulic tubing and duplex tubing are free of surface contamination, we use a dye penetrant test

Duplex steel tube

- Size: 4mm to 219mm

- Wall thickness: 0.3mm to 50mm

- OD: 6.00 mm – 25.4mm

DSS extruded tube

- Length: upto 6mm

- Application: power plants

- Yield strength: 450 MPa

Duplex annealed tubes

- Temp: 22 to 617°F (-30 to 325°C)

- Coating: galvanized

- Surface finish: annealed & pickled

We supply high quality duplex annealed tubes overall Mumbai, India. stay connect with us

A DSS welded tube offers several benefits that make it a preferred choice in hydraulic system applications.

- Corrosion Resistance: This tubing exhibits excellent corrosion resistance, especially in aggressive environments.

- High Strength: The hydraulic tubing has higher strength compared to austenitic stainless steel.

- Ductility and Toughness: DSS hydraulic tubing combines high strength with good ductility and toughness.

DSS annealed tubes can be tested for their durability using various methods such as:-

- Salt Spray Test: This test exposes the tubes to a highly corrosive salt spray environment to evaluate their resistance to corrosion.

- Intergranular Corrosion Test: This test determines the DSS tubes’ susceptibility to intergranular corrosion.

- Hydrostatic Pressure Test: This test evaluates the DSS tubes’ ability to withstand internal pressure.

DSS coiled tubing is produced by joining two separate pieces of DSS. On the other hand, seamless DSS tubing is manufactured from a solid billet of DSS.

Seamless DSS tubing is considered structurally stronger and more uniform than welded tubes due to its continuous, uninterrupted structure But welded DSS tubing is more readily available and generally more cost-effective as compared to DSS seamless tubing.

Why To Choose Our Duplex Tubes?

✅Premium-Grade Raw Materials

✅Advanced Manufacturing Standards

✅Superior Corrosion & Pressure Resistance

✅ End-to-End Support