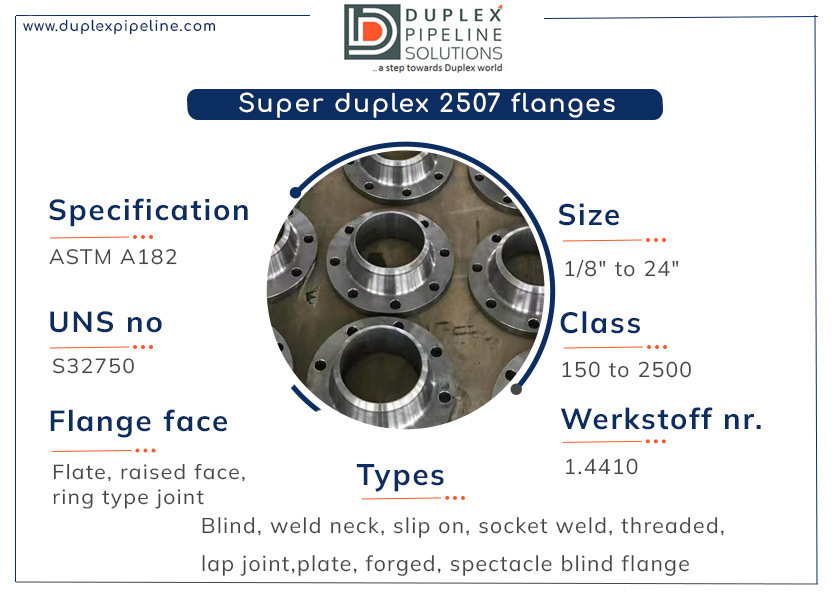

Super duplex 2507 flanges

Flange manufacturers properly clean the flange surfaces to ensure they are devoid of all contaminants including grease, oil, rust and scale. They check and verify if the flanges are accurately aligned and sync together with the provided gap for welding processes.

Super duplex 2507 flanges are typically welded using the gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW) process. Parameters such as current, voltage, travel speed, and shielding gas flow rate are then adjusted to achieve the desired weld bead shape.

2507 slip on flange manufacturer in India

Alloy 2507 blind flange exhibits high tensile strength typically in the range of 750-1000 MPa as compared to other flange types. Thus, this grade flange can better withstand significant mechanical forces and pressures than other flanges.

The yield strength of the 2507 super duplex slip-on flange is typically much higher than the 550 MPa limit. This excellent high yield strength boosts the overall structural integrity of the flange material which is rarely found in other flange types.

Finding custom sizes of super duplex 2507 blind flange in accordance with the ASME B16.5 standard? check our inventory

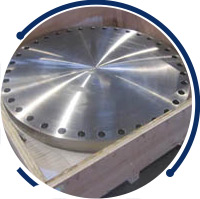

Alloy 2507 blind flange

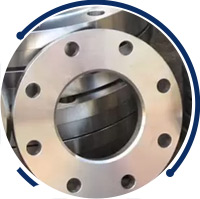

2507 super duplex slip on flange

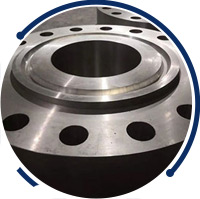

SDSS 2507 weld neck flange

SDSS 2507 weld neck flange is employed in subsea equipment such as subsea manifolds, risers, flowlines, and jumpers. These flanges provide a reliable connection between different components, ensuring integrity and durability in harsh underwater environments.

Din 1.4507 socket weld flange is employed in oil and gas pipelines for connecting sections of pipe and allowing easy access for inspection. These flanges offer reliable joints that withstand high-pressure and high-temperature conditions, along with the corrosive nature of the conveyed fluids.

Looking for a reliable super duplex stainless steel 2507 flanges maker in Mumbai? contact us, we produce high quality SDSS threaded flange

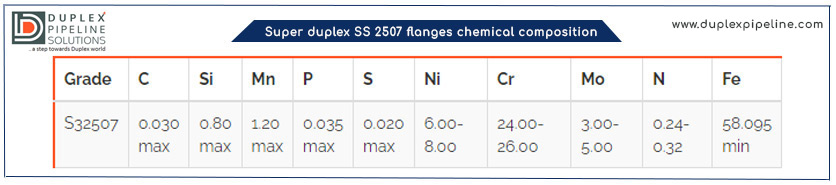

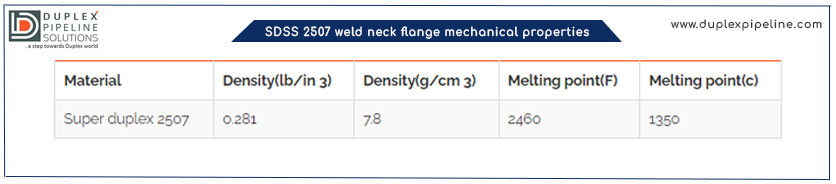

Check the chemical composition, mechanical strength, and equivalent grades of DIN 1.4507 socket weld flange before ordering

Din 1.4507 socket weld flange

- Coating: oil black paint

- Type: forged/ threaded

- Production process: forging, casting

Duplex 2507 rtj flange

- Size: 1/2″-48″

- Pressure rating: 150-2500

- Tepm: -50°F to +600°F

25cr super duplex sorf flange

- Tensile strength: 485 min

- Application: oil and gas, petrochemical

- Production process: machined

Manufacturer of SDSS 2507 weld neck flange from 150 to 2500 pressure class, check dimensions and weight chart

We are top super duplex 2507 flanges manufacturers in India, we provide high quality flanges for oil and gas industries

The pressure rating of duplex 2507 RTJ or Ring Type Joint flanges varies based on factors including the size, class, and design standards employed. Typically, 25cr super duplex sorf flange is available in various pressure classes such as 150, 300, 600, 900, 1500, and 2500.

2507 stainless steel lap joint flange exhibits exceptional resistance to pitting and crevice corrosion. These flanges also demonstrate high resistance to chloride-induced stress corrosion cracking.

This flange exhibits high resistance to intergranular corrosion which is the corrosion that occurs along grain boundaries due to sensitization. They demonstrates good resistance to various acidic environments, including sulfuric acid, hydrochloric acid, and phosphoric acid.

The common sizes and dimensions of flanges can vary based on the applicable standards. The pressure classes of 2507 super duplex stainless steel wnrf flange are 150, 300, 600, 900, 1500, and 2500. The common size and dimension of 2507 steel blrf flange is 1/2″ to 48″ or 15 NB to 1200 NB or can be custom build as per project requirements.