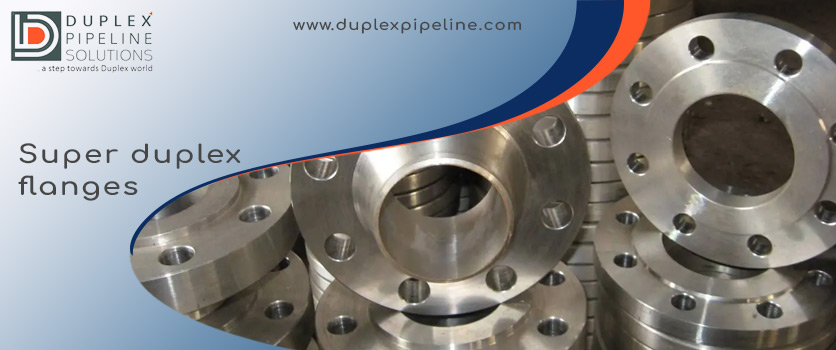

Super duplex flanges

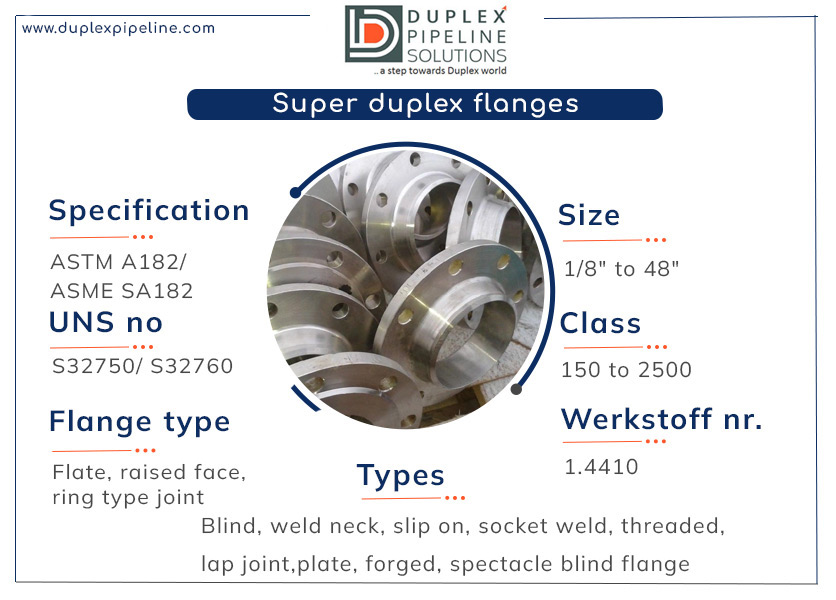

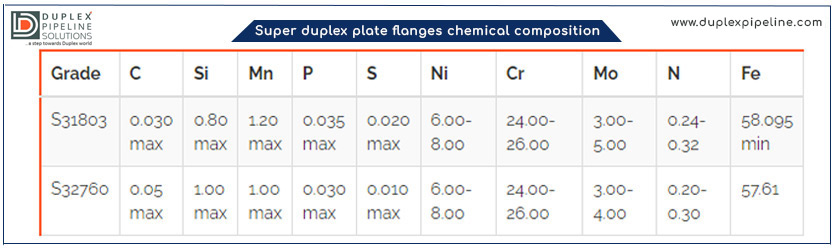

These SD flanges are typically available in grades such as S32750 also known as F53 and S32760 or F55. The SDSS grades offer excellent corrosion resistance and mechanical properties compared to standard duplex stainless steel.

Other steel grades such as UNS S32760 may also be used for SDSS materials depending on specific needs and requirements. These grades of SDSS provide superior corrosion resistance as compared to other standard austenitic stainless steel.

SDSS blind flange manufacturer in India

Super duplex flanges are resistant to a wide range of corrosive conditions including chloride-induced stress corrosion cracking. The SDSS flanges offer high strength and can withstand heavy loads and pressures.

We are a leading super duplex flanges manufacturer in India, have higher yield and tensile strength compared to standard DSS. They also show excellent resistance to fatigue which makes them suitable for cyclic loading applications.

These stainless flanges have higher yield and tensile strength compared to standard duplex stainless steels. They also show excellent resistance to fatigue which makes them suitable for cyclic loading applications.

Duplex pipeline specializes in the manufacture of super duplex slip on flange, check the difference between Super duplex steel forged flange and threaded flanges

Super duplex flanges

Super duplex pipe flanges

SDSS socket weld flange

Forced flanges have a raised face or a flat face with bolt holes. This allows the forced flange to be easily welded to other pipes or flanges without any hassles and difficulties.

SDSS threaded flanges, on the other hand, have internal threads. The threads in the flange provide the means for a secure connection without requiring welding

To ensure that you select the right super duplex steel flanges for your application, check our specification table

We are high quality super duplex stainless steel flanges supplier in Mumbai

Quality of super duplex weld neck flanges, we employ rigorous testing methods throughout the manufacturing process

Super duplex blind flange

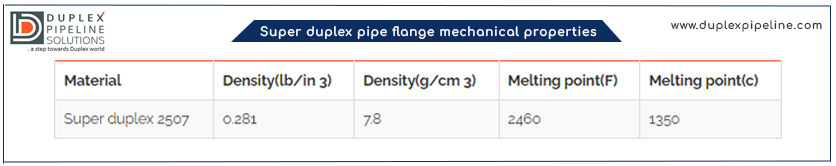

- Tensile Strength: 415 MPa

- Coating: oil varnishe

- Pressure class: 150 – 2500

Super duplex slip on flange

- Application: airpspece

- Size: 1/2″ – 48″

- Type: blind,slip on, weld neck

SDSS lap joint flange

- Face type: Rtj, RF, FF, T&G

- Yield Strength: 290 MPa

- Elongation: 50mm

Our super duplex stainless steel threaded flange are offered in a variety of equivalent grades to guarantee compatibility with various piping systems

Visual inspection involves a visual examination of the SDSS blind flange for any visible defects, such as surface irregularities and cracks. On the other hand, in dimensional inspection, verifies the dimensions and tolerances of the blind flange such as diameter and thickness are checked.

The Magnetic Particle Testing Method is used by steel manufacturers to detect surface defects in the SDSS flange such as cracks or discontinuities. RT process uses X-rays or gamma rays to examine the internal structure and defects of the blind flange.

SDSS weld neck flanges offer excellent corrosion resistance, especially in aggressive environments. The use of super duplex pipe flanges considerably reduces the danger of corrosion-related failures and leaks in the piping system

A SDSS slip on flange with high strength and toughness qualities, ensure structural integrity and withstand heavy loads. A SDSS socket weld flange offers a secure and leak-free connection when properly welded to the pipes.

The precise alloying elements and their percentage composition affect a flange’s capacity to resist corrosion in diverse situations. The chromium layer of the SDSS threaded flange offers excellent corrosion resistance by acting as a barrier against agents.

Molybdenum enhances the corrosion resistance of the SDSS lap joint flange especially in environments containing chlorides. It increases the resistance of the flange against pitting and crevice corrosion.