Super duplex pipe

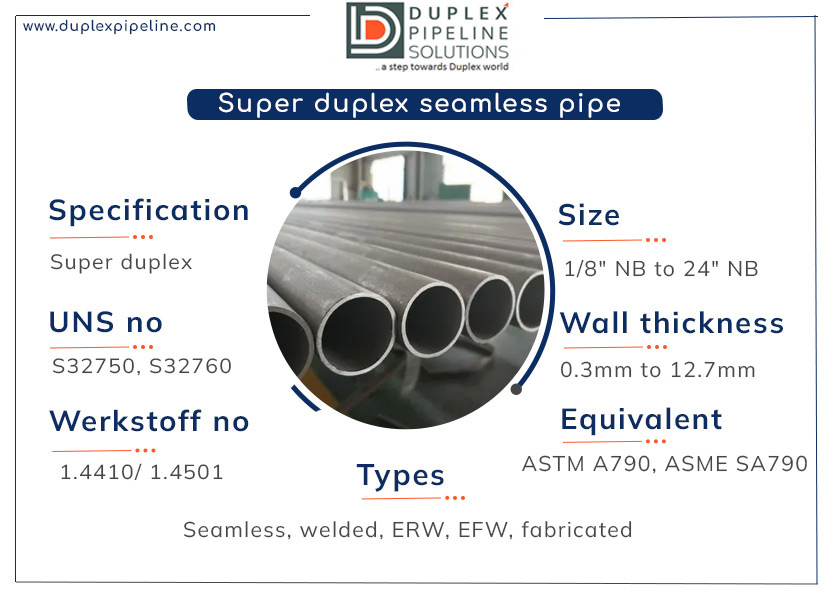

A Super Duplex tube is a tube that is produced from a SDSS alloy. A super duplex seamless pipe is a highly resistant material that possesses good strength and durability characteristics.

We are duplex pipe supplier in Mumbai, the SDSS pipe possesses a balanced microstructure consisting of ferrite and austenite phases. The duplex microstructure causes the SD pipe to possess superior mechanical and corrosion resistance properties in corrosive environments.

Super duplex stainless steel welded pipe supplier in India

PROPERTIES:-

- Corrosion Resistance: These SD pipes exhibit excellent corrosion resistance, particularly in aggressive environments such as chloride-rich and alkaline conditions.

- Exceptional Strength: They possess excellent tensile and yield strength as compared to conventional duplex or austenitic stainless steel grades.

- Good Weldability: A SDSS pipe exhibit good weldability and allows easy fabrication and joining operations without any complexity.

- Cost-Effective Solution: Despite their excellent corrosion properties, SDSS pipes offer a cost-effective solution as compared to some other alloys in the market.

- Thermal Properties: Better thermal conductivity and lower thermal expansion than austenitic steels, ensuring greater dimensional stability under temperature changes.

CHARACTERISTICS:-

- High Strength

Nearly double the yield strength of conventional stainless steels like 304 and 316. - Excellent Corrosion Resistance

Outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking, especially in chloride-rich environments (e.g., seawater, chemical plants). - Dual-Phase Microstructure

Contains roughly 50% ferrite and 50% austenite, combining the best properties of both phases. - Superior Fatigue Resistance

Handles cyclic loading and vibration better than standard grades. - Good Weldability

Can be welded using standard techniques with appropriate procedures to maintain phase balance. - High Resistance to Erosion and Wear

Ideal for use in abrasive environments like offshore and flow lines. - Thermal Stability

Performs well across a wide range of temperatures with low thermal expansion. - Cost Efficiency

Long service life and reduced maintenance make it a cost-effective solution over time. - Slightly Magnetic

Due to its ferritic content, the pipe is slightly magnetic—useful in some detection and installation applications.

To assure the quality and avoid any future problems, we utilize dimensional checks on the super duplex seamless pipe

Super duplex square pipe

SDSS efw pipe

Schedule 40 SDSS pipe

🔍 Key Dimensional Inspection Techniques:-

1. Ultrasonic Testing (UT):

- Purpose:

UT is a non-destructive testing method used to measure wall thickness and detect internal imperfections in the pipe. It involves sending sound waves into the pipe and analyzing the echoes to determine the thickness and identify any flaws. - Benefits:

UT is highly accurate, efficient, and can be used to inspect pipes without damaging them.

- Visual Inspection:

- Purpose:

This involves a thorough examination of the pipe’s surface to detect any visible imperfections, such as cracks, scratches, or uneven weld beads. - Benefits:

Visual inspection is a quick and inexpensive method to identify surface defects.

- Radiographic Testing (RT):

- Purpose:

RT uses X-rays or gamma rays to inspect the internal structure of the pipe, particularly the weld seam. It’s used to identify internal defects like lack of fusion or porosity in the weld. - Benefits:

RT provides a permanent image record of the weld and is effective for verifying weld integrity.

- Other Potential Techniques:

- Calipers and Micrometers: These tools are used for precise measurement of the pipe’s outside diameter (OD), inside diameter (ID), and wall thickness.

- Laser Scanning and Optical Methods: These methods can be used for accurate measurements of dimensions, roundness, and straightness.

- Tape Measures and Rulers: These tools are used for length measurements and quick reference checks.

- Hydrostatic Testing: This involves pressurizing the pipe with water to detect leaks or flaws.

- Magnetic Particle Testing (MPT): This method is used to detect surface and near-surface flaws in ferromagnetic materials.

- Liquid Penetrant Testing (PT): This method is used to detect surface flaws in non-ferromagnetic materials.

We are super duplex stainless steel ERW pipe manufacturers in Mumbai, Discover there applications

We are high quality super duplex stainless steel pipe manufacturer in Mumbai

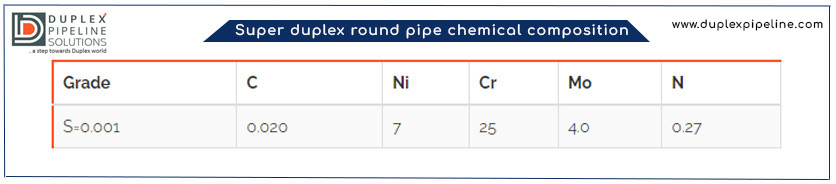

To check chemical composition of super duplex round pipe, contact us

Super duplex round pipes

- Size: 6 – 710mm

- Wall thickness: 1.0mm-20mm

- Application: chemical, pulp

SDSS seamless pipe

- O.D. x I.D. 1/16″. x 0.005″

- Shape: Round

- Temperature range: 1100°C to 1250°C

SDSS welded pipes

- Yield strength: psi – 80000

- Tensile strength: 800 MPa

- Coating: annealed

To know more about the sizes and wall thicknesses of super duplex square pipe, check our technical data sheets

Chemical composition of Super duplex round pipe

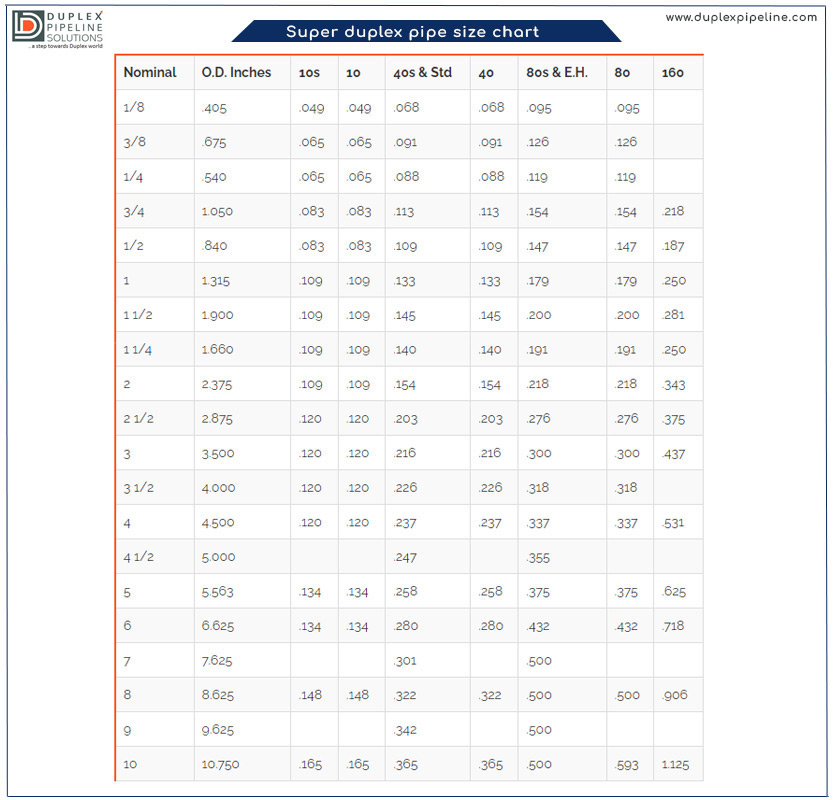

Size chart of super duplex pipe

- Oil industry: These SDSS pipes are employed because of their excellent corrosion resistance in the oil and gas industry, particularly in offshore and subsea applications.

- Chemical processing: These SD pipes are suitable for chemical processing plants where resistance to highly corrosive substances is needed

- Desalination: A SDSS exhaust pipe is employed in desalination plants and water treatment facilities.

- Pulp and Paper Industry: SDSS pipes find usage in the pulp and paper industry, particularly in the chemical recovery and bleaching processes.

Seamless super duplex pipes pressure ratings are calculated by a number of parameters like pipe size and industry specifications. Most widely adopted design codes used for pipe pressure rating calculation are ASME B36.19 and APL 5L.

SDSS round pipes in accordance with the ANSI/ASME B36.19 standard are typically rated from 150 to 2500 psi or 1 MPa to 17 MPa. Seamless pipes in accordance with the API 5L standard range from 3,000 to 20,000 psi or 20 MPa to 138 MPa.

🔹 Key Advantages of SDSS Polished Pipe:

✨ Enhanced Corrosion Resistance

The polished surface minimizes crevices and surface roughness, reducing areas where corrosion could initiate—especially beneficial in marine, chemical, and pharmaceutical applications.

📏 Superior Dimensional Accuracy

Seamless construction ensures uniform wall thickness and eliminates weak points caused by welding, leading to high pressure tolerance and structural integrity.

💪 High Strength & Durability

Offers twice the strength of conventional austenitic stainless steels, with excellent resistance to stress corrosion cracking and fatigue.

🧼 Easy to Clean & Hygienic

The smooth polished finish is easy to clean, making it ideal for hygienic industries such as food processing, biotech, and water purification.

🔧 Improved Aesthetic Appearance

Suitable for visible installations and architectural applications where a premium look is desired.

🔥 Excellent Heat & Chemical Resistance

Can withstand high temperatures and aggressive chemicals due to its alloy composition and surface finish.

🧲 Non-porous & Low Surface Contamination

Polishing reduces surface porosity, limiting particulate accumulation and microbial growth.