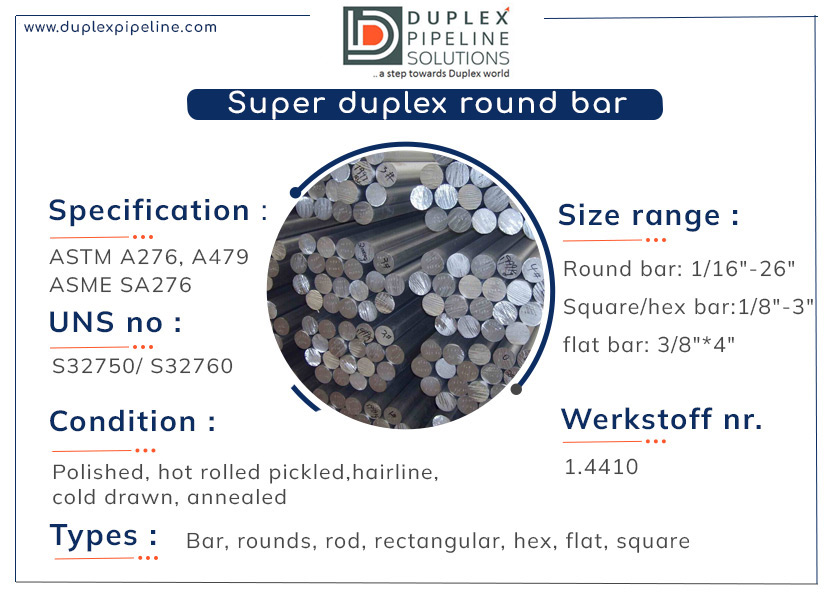

Super duplex round bar

These round bars are a type of steel product that belongs to the category of super duplex stainless steel. The steel round bars find extensive usage in industries such as oil and gas, chemical processing, pulp and paper, and desalination plants. A super SDSS round bar is known for its excellent mechanical properties and corrosion resistance quality.

Super duplex stainless steel square bar supplier in India

A super duplex rod exhibits exceptional corrosion resistance, particularly in aggressive environments such as chloride-rich and acid conditions. The SDSS flat bar has an extremely high resistance to pitting, crevice corrosion, and stress corrosion cracking.

SD rods exhibit excellent toughness which refers to their ability to absorb energy and resist fracture. These rods also demonstrate high fatigue resistance, allowing them to sturdily withstand repeated cyclic loading without failure.

To learn more about how heat treatment impacts the mechanical characteristics of a super duplex steel rod, feel free to contact us.

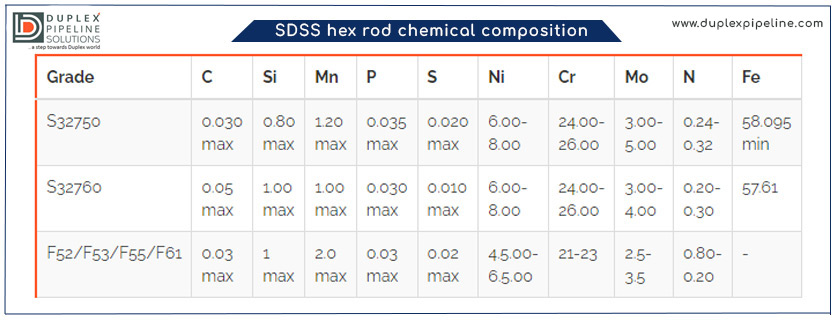

Super duplex steel hex bar

Super duplex flat bar

SDSS square bar

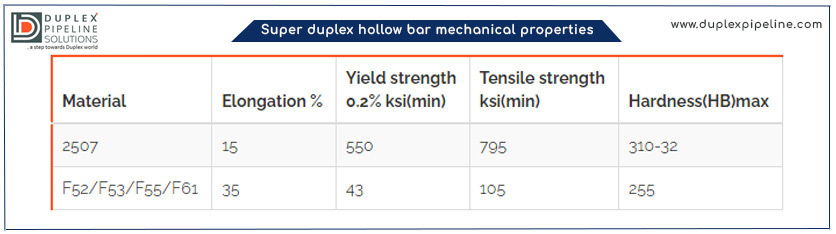

Annealing is a heat treatment process in which the super duplex round bar supplier in India heat the bar to a specific temperature. This process helps dissolve any precipitates or carbides formed during hot working or welding, and it restores the material’s microstructure.

Another heat treatment process employed for the EN 10088-3 flat bar is solution annealing which is performed at around 1050-1100°C. This annealing process can dissolve and homogenize any precipitates that may have formed during the manufacturing of the bar.

To view the range of sizes we offer for super duplex hex bar, please refer to our specification tables

We are high quality and corrosion resistant super duplex rod manufacturer in Mumbai

We are top 7 super duplex bright bar supplier in India, we use appropriate welding techniques, such as TIG or MIG welding, check applications

Super duplex rod

- Diameter: 10 mm – 200 mm

- Finish: bright, polish & black

- Length: 1 – 2000mm

Super duplex steel rounds

- Size: 3.0 – 50.8 mm

- Form: round, square, hex, flat

- Application: power generation

SDSS round bar

- Testing: pitting resistance

- Melting point: 1400 – 1455°C

- Tolerance: 2.5%

To read about the chemical and mechanical properties of polished super duplex flat bar, please refer to our technical data sheets

Employ suitable welding techniques for SDSS such as gas tungsten arc welding (GTAW or TIG), and shielded metal arc welding (SMAW or stick welding). Choose the specific technique based on factors such as joint design, welding position, and project demands or requirements.

Set appropriate welding parameters including current, voltage, and travel speed based on the specific welding process and the thickness of the SDSS hex bar. After completing the welding, perform post-weld treatments to restore the mechanical properties and corrosion resistance of the joint.

A ASTM A276 SDSS square bar is employed in the manufacturing of downhole tools such as drilling tools, completion tools, and wellbore tools. These tools mostly operate in demanding and challenging downhole conditions such as high temperatures, high pressures, and corrosive fluids or gases.

Polished SDSS bars are employed in the manufacturing of heat exchangers, condensers, and pressure vessels. These instruments necessitate materials with high strength, corrosion resistance, and compatibility with fluids and the SD bars are a perfect fit for this.

The price of a A479 super duplex hollow bar can vary based on the size, grade, supplier, market conditions, and quantity ordered. The prices of the SDSS solid rounds can change over time due to fluctuations in the cost of raw materials. Acquire accurate and up-to-date prices for hollow bars from the best suppliers, distributors, or manufacturers.