Super duplex tube

Super duplex tube refer to a type of tubing made from a SDSS material. This tube is a high-performance alloy that combines the desirable properties of both austenitic and ferritic stainless steel.

Super duplex stainless steel seamless tubing supplier in India

We are super duplex seamless tube manufacturer in Mumbai, hot rolling and cold rolling are the two processes usually employed for preparing and manufacturing the SDSS tube. The type of rolling process used depends on the specific application or manufacturing requirements for the square tube.

Super duplex steel welded tube can be welded using various techniques. also get super duplex tubing with excellent corrosion resistance and high strength

Super duplex ss tube

SDSS welded tube

Super duplex round tube

TIG welding, also known as Gas Tungsten Arc (GTAW), is a popular technique for welding a super duplex seamless tube. SMAW, commonly known as stick welding, is a manual welding process for a SDSS annealed tube that employs consumable electrodes. FCAW is another welding technique that uses tubular wires filled with flux instead of a solid electrode.

We are super duplex ERW tube manufacturers in Mumbai, check advantages of using Super duplex stainless steel tubing in oil and gas industries

We are a leading super duplex tube supplier in India

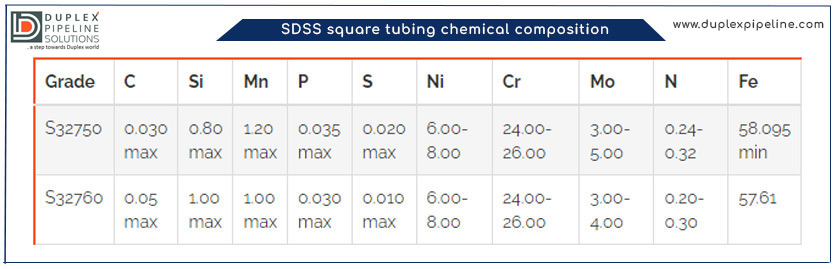

To know more about the chemical composition of super duplex annealed tube, visit us

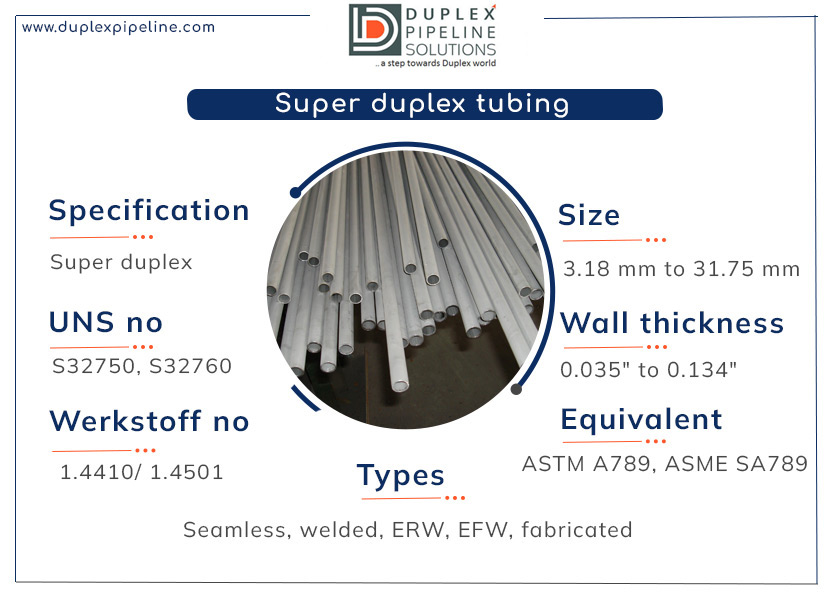

Super duplex seamless tube

- Surface finish: pickled

- Size: 1/2 to 24″

- Length: 0.51mm To 25.4mm

SDSS annealed tube

- wall thickness: 0.5mm to 20mm

- Application: oil and gas

- Brinell hardness: 290 (Rc31)

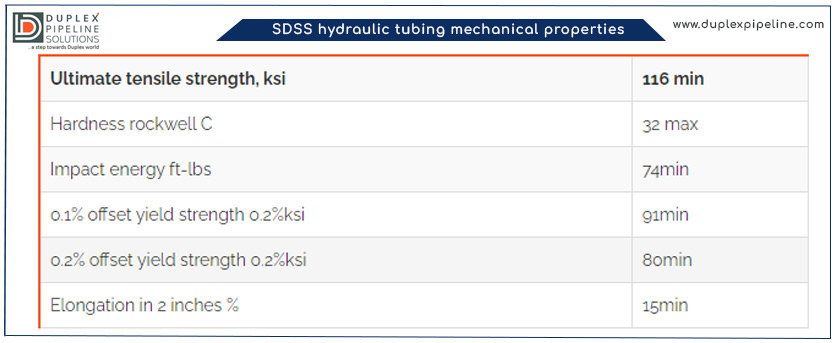

Super duplex hydraulic tubing

- Tensile strength: 620 MPa

- Packaging type: box

- Form: hydraulic, rectangular, square

Contact us for additional specifications on surface finish and mechanical properties of SDSS hydraulic tubing

A SDSS honed tube is employed in sectors where high corrosion resistance, strength, and durability are required. These honed tubes are commonly utilized in hydraulic and pneumatic systems where they serve as cylinder barrels.

This SDSS hydraulic tubing is highly employed in various automotive and transportation industry applications. The mining and mineral processing industry highly relies on honed tubes in equipment utilized for mineral extraction, processing, and refining purposes.

SDSS annealed tubes exhibit high resistance to corrosion, particularly in aggressive environments such as offshore oil and gas production. These SD tubes show excellent resistance to pitting, crevice corrosion, and stress corrosion cracking as compared to SS tubing.

Because of its high mechanical strength, SDSS coiled tubing is highly popular in oil industries. This strength enables the tubes to sturdily withstand high-pressure conditions usually prevalent in offshore oil and gas production.

SDSS square tubing can handle significantly higher pressure levels compared to standard austenitic or ferritic stainless steels. Square tubing sturdily retains its mechanical properties and corrosion resistance even at elevated temperatures.

SDSS tubing demonstrates high oxidation resistance even at elevated temperatures. The SDSS material forms a protective oxide layer on its surface which helps prevent oxidation and scaling at high temperatures.