UNS S31803 elbow

Pressure rating entails the maximum allowable pressure that a component such as a pipe or fitting can withstand without experiencing any failure, or deformation. The pressure rating for elbows can vary depending on the material, dimensions, wall thickness, and manufacturing standards.

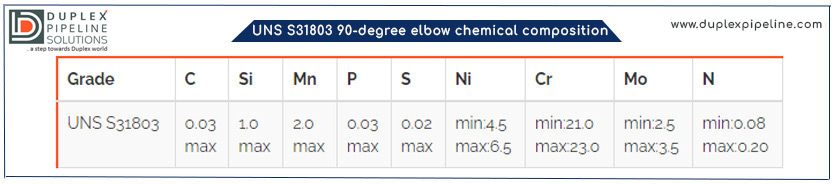

The pressure rating of the UNS S31803 elbow ranges from 1200 Pound Square Inch PSI to 18,000 PSI based on the class. ASTM A182 UNS S31803 miter elbow has the following classes which are 150, 300, 600, 900, and many more.

A815 S31803 pipe elbow manufacturer in India

A815 S31803 90-degree elbow is commonly employed in offshore and onshore oil and gas installations. This elbow is utilized in pipelines, process piping, and equipment for transporting and processing oil, gas, and other products.

A815 UNS S31803 sweep elbow is suitable for chemical processing plants, refineries, and petrochemical facilities. They are used in pipelines, reactors, heat exchangers, and other equipment handling aggressive chemicals and corrosive environments.

At the lowest price, get ultrasonic testing and visual inspection for ASTM A815 UNS S31803 long radius elbow

ASTM A815 WP-W welded elbow

SA 815 UNS S31803 Long Radius Elbow

A815 S31803 90-Degree Elbow

ASTM A815 WP-W welded elbow shows good resistance to general corrosion caused by acids, alkaline solutions, and chlorides. These elbows are particularly resistant to pitting and crevice corrosion which are common in chloride-rich environments.

A815 S31803 butt weld elbow exhibits high resistance to chloride-induced stress corrosion cracking which is a critical form of corrosion. They also show good resistance to sulfide stress corrosion cracking which can occur in environments with hydrogen sulfide or H2S and water

Get SA 815 UNS S31803 welded elbow standard size ranges from 1/2 inch to 24 inches in diameter, we offer free delivery in Mumba

We are specialized in different sizes, corrosion-resistant, and long-lasting ASTM A815 UNS S31803 short radius elbow. call us right away!

ASTM A815 UNS S31803 45-Degree Elbow

- Diameter: 3-5″

- Connection type: elbow

- Color: silver

A815 S31803 Sweep Elbow

- Surface treatment: polished

- Wall thickness: 10-15mm

- Bend angle: 90 degree

A815 UNS S31803 Butt Weld Elbow

- Product type: long radius

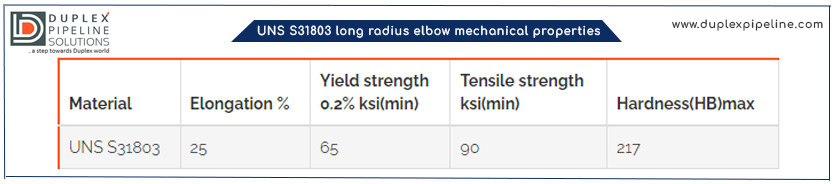

- Tensile Strength (Mpa): 515

- Yield Strength: 290 MPa

View pressure rating, tolerance, and surface finishes of A815 S31803 90-degree elbow

SA 815 UNS S31803 long-radius elbow exhibits excellent corrosion resistance, particularly in aggressive environments containing chlorides, and acids. These elbows offer good weldability properties, allowing for ease of fabrication and installation without any issues. They have excellent fatigue resistance, enabling them to withstand cyclic loading and pressure fluctuations without premature failure.

Seamless elbow fittings are manufactured from a single piece of stainless steel without any welding or joining. These fittings exhibit excellent corrosion resistance similar to the base material.

ASTM A815 UNS S31803 seamless elbow exhibit a smooth and uniform appearance since they are produced from a single billet without any welded joints. Welded elbow fittings are formed by joining two or more pieces of stainless steel through different welding techniques.

ASTM A815 UNS S31803 seamless elbow has a smooth and uniform appearance since they are produced from a single billet without any welded joints. Welded components have visible welded joints where the sections of the steel are joined together.

The ASTM A815 specification does not specify minimum yield strength requirements for fittings such as short radius elbows. Try to refer to the material specification to find out the yield strength of an ASTM A815 UNS S31803 short radius elbow product.