UNS S31803 end cap

These end caps are used in both process piping and plumbing systems across various industries including oil and gas, and chemical processing. Pressure vessels often need end caps to properly seal the openings and maintain the integrity of the vessel.

UNS S31803 end cap is utilized in the construction of pressure vessels such as tanks, reactors, and heat exchangers. They provide a secure closure for these vessels ensuring the containment of fluids or gases under pressure.

S31803 cap fittings manufacturer in India

ASTM A815 UNS S31803 cap fitting exhibits good toughness which makes them more resistant to impact and vibration. Using these cap fittings helps protect the ends of pipes from corrosion ensuring the integrity and longevity of the piping system.

ASTM A182 S31803 cap offer enhanced mechanical strength allowing them to sturdily withstand high-pressure and high-stress conditions. This dual phase structure mainly contributes to the material’s superior strength, toughness, and resistance to stress corrosion cracking SCC.

Get high-quality UNS S31803 buttweld cap stock that has a very strong resistance to surface and crevice corrosion

ASTM A815 UNS S31803 cap fitting

A815 S31803 buttweld cap

ASTM A815 WP-W pipe end cap

The maximum allowable temperature for an A815 S31803 buttweld cap will depend on the duration of exposure, and the presence of corrosive media. 1/2″, 3/4″, and 1″sized end caps can endure temperatures of 600°F without deformation or failure.

The pressure rating of the ASTM A815 UNS S31803 pipe cap depends on factors such as the wall thickness, diameter, and manufacturing standards. Pressure ratings of the caps range from 1500 psi for 1/2″ size to 7500 psi for 2″ size.

We supply ASTM A815 UNS S31803 pipe cap with NDT testing and visual inspection for great quality and high performance

Compare our price with other manufacturers of SA 815 UNS S31803 weld cap before purchasing, check dimension and tolerance.

SA 815 UNS S31803 weld cap

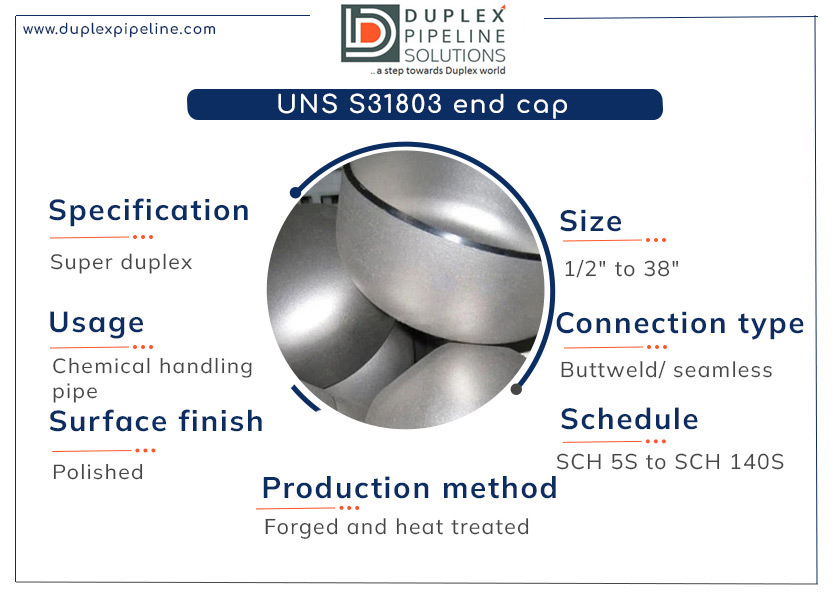

- Size: 1/2″-30″

- Schedule: SCH 5S – SCH 120S

- End connection: Seamless

A815 S31803 seamless cap

- Surface finish: mirror finish

- Usage: chemical handling pipe

- Production method: forged & heat treated

ASTM A815 UNS S31803 pipe cap

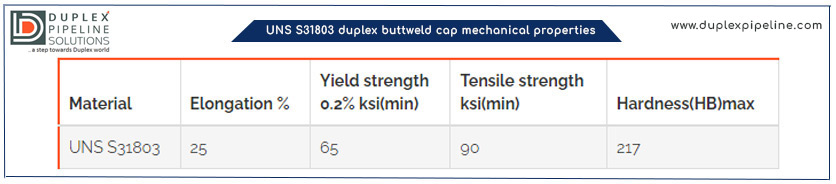

- Tensile Strength (Mpa): 515

- Yield Strength: 290 MPa

- Elongation: 40%

Distributor of A815 S31803 seamless cap in class 150 to 2500. for more information contact us now!

The temperature and pressure ratings for the A815 S31803 buttweld cap depend on the size, wall thickness and applicable industry standards. In general, these buttweld caps are designed to withstand high-temperature and high-pressure conditions typical in piping systems.

Pressure ratings are typically given as maximum allowable working pressures MAWP at specific temperatures. Consult the relevant industry standards and manufacturer’s data for accurate and up-to-date information on temperature and pressure ratings for the ASTM A815 UNS S31803 pipe cap.

Visual inspection assesses the overall appearance, surface condition, dimensions, and any visible defects of the ASTM A815 WP-W pipe end cap. The dimensional inspection entails verifying the dimensions and tolerances of the cap ensuring it meets the specified requirements.

The diameter of the SA 815 s31803 round end cap can range from a few inches to several feet depending on the application. Tolerances for the caps depend on the applicable standards, dimensions such as wall thickness and length, and the manufacturing process used