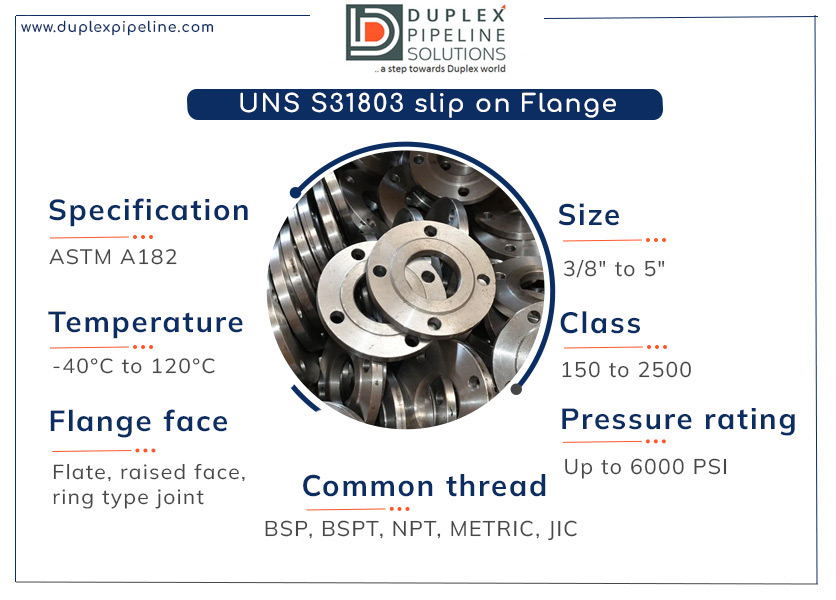

UNS S31803 Slip on Flange

This flange exhibits excellent corrosion resistance particularly in environments containing chlorides such as seawater. It consists of a balanced mixture of austenite and ferrite phases that contributes to the material’s enhanced properties

UNS S31803 slip on flange can be easily welded to the pipe using various welding techniques including TIG welding, and MIG welding. This material can sturdily withstand mechanical stresses and shocks without fracturing or deformation.

SA 815 S31803 slip blind flange manufacturer in India

ASTM A815 UNS S31803 SORF Raised Face Slip-On Flange has a raised face on the flange’s sealing surface. This raised face assists to create a seal when the ASTM A815 WP-S UNS S31803 so ff flange is joined to the mating flange.

Slip-on ring type joint ASTM A815 WP-S UNS S31803 so ff flange has a ring-type joint groove on the sealing surface. This flange can accommodate a metallic ring gasket and provide a reliable and leak-free seal in high-pressure applications.

A815 S31803 hubbed slip on flange available in class 150 – 2500 at best price, view pressure rating, dimenssion and tolerance

ASTM A815 UNS S31803 slip on raised face flange

A815 S31803 hubbed slip on flange

ASTM A815 WP-W SORF flange

The cost of the A815 S31803 hubbed slip on flange product can vary based on the size, pressure rating, and manufacturing. SA 815 UNS S31803 slip blind flange has a higher cost as compared to other popular steel grades which are commonly used to produce flanges.

We supplier ASTM A815 WP-W slip on raised face flange in 1/2 inch(15 NB) to 48 inch (1200NB) size range

We provide MTC with all delivery of ASTM A182 UNS S31803 SORF flange, connect with us to know more about specification properties

A815 S31803 reducing slip on flange

- Application: petrochemical

- Size: 1/2″ – 48″

- Pressure class: 150 – 2500

ASTM A815 UNS S31803 slip on pipe flange

- Type: slip blind flange, so ff flange

- Face type: Rtj, RF, FF

- Coating: anti-rust painting

SA 815 s31803 slip on forged flange

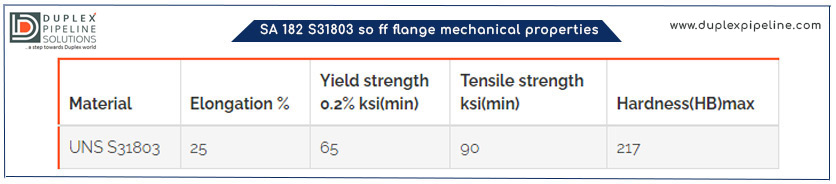

- Yield Strength: 290 MPa

- Tensile Strength: 415 MPa

- Elongation: 50mm

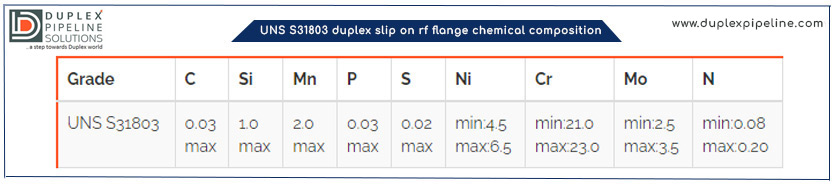

Dont forget to check our SA 815 s31803 slip on forged flange chemical composition and mechanical properties

ASTM A815 WP-W slip on raised face flange is designed for easy installation making them a popular choice in various applications. The slip-on design allows the flange to be easily slipped over the pipe end and makes alignment and fitting simpler.

SA 815 s31803 slip on forged flange exhibits good corrosion resistance particularly in aggressive environments containing chlorides, acids, or high temperatures. The corrosion resistance property helps lower damage to the flange surface and ensures the integrity of the piping unit.

The slip-on design allows for slight movement and adjustment before welding and makes it easier to align the flange with the mating flange. The raised face creates a compressed seal when the flange is tightened against the mating flange, preventing leaks.

SA 815 UNS S31803 slip blind flange is widely used in the oil and gas industry for connecting pipelines of different diameters. In the chemical industry, these flanges are utilized for connecting pipes in chemical processing plants.

SA 815 s31803 slip on forged flange find application in water treatment facilities where pipes need to be connected for water distribution. In pharmaceutical manufacturing plants, these flanges are used to connect pipes of different sizes for the transfer of fluids and chemicals.

GTAW is a precise and high-quality welding process commonly used for joining A815 UNS S31803 slip joint flange. GMAW is another semi-automatic or automatic welding process suitable for joining the A815 S31803 reducing slip on flange. It uses a continuous wire electrode and a shielding gas, typically a mixture of argon and carbon dioxide to protect the weld zone.