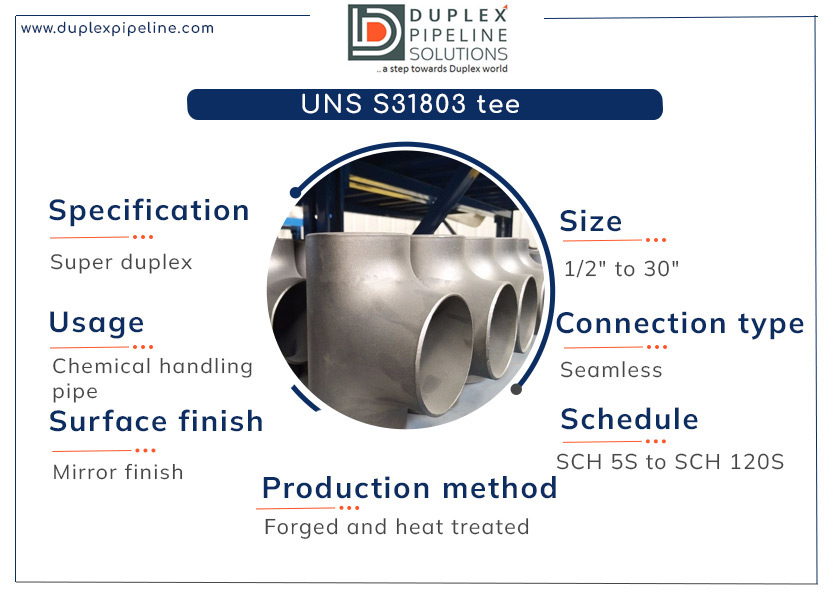

UNS S31803 tee

It is a tee-shaped fitting produced from a popular grade of steel that offers a combination of high strength and corrosion resistance. These fittings are employed in piping systems to facilitate branching or redirection of flow, ensuring efficient fluid transportation.

UNS S31803 tee is utilized in desalination systems as they exhibit good resistance to seawater corrosion and can endure the high temperatures. They find application in petrochemical refineries where they are exposed to a wide range of aggressive chemicals and high-temperature environments.

A790 S31803 buttweld tee manufacturer in India

The manufacturer processes the raw material into billets and hot-roll or forges them to achieve the desired dimensions. The ASTM A815 UNS S31803 equal tee billet is placed in a forming press or extrusion machine where it is shaped into the tee form.

After the initial forming, the ASTM A182 S31803 pipe tee undergoes machining operations to refine its dimensions and achieve precise angles. Manufacturers employ heat-treatment procedures such as solution annealing or stress relieving to enhance the mechanical properties and stability of the tee.

We offer SA 815 UNS S31803 seamless tee in Mumbai with high corrosion and resistance

A815 S31803 unequal tee

ASTM A815 WP-W seamless tee

SA 815 UNS S31803 reducing tee

The temperature range for A815 S31803 unequal tee can vary based on the specific area or application, and the applicable standards or codes. This tee can work sturdily in applications with temperatures ranging from sub-zero temperatures up to around 600°C to 650°C or 1112°F to 1202°F without deformation.

When it comes to temperatures higher than this limit, consult the material data sheets and design codes of the ASTM A815 WP-S UNS S31803 split tee. It us crucial to consider factors such as thermal cycling, and the duration of exposure when assessing the temperature limits for the tee.

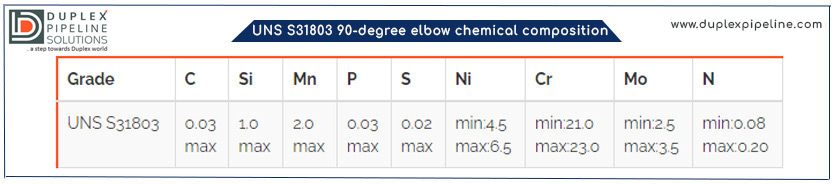

Looking to buy cheap A815 S31803 equal tee? check wall thickness and chemical composition here

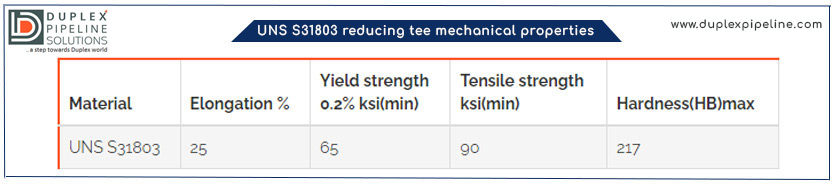

Supplier of ASTM A815 UNS S31803 reducing tee with tensile test and charpy impact test

A815 S31803 butt weld tee

- Size: 1/2″-30″

- Schedule: SCH 5S – SCH 120S

- End connection: Seamless

SA 815 s31803 flanged tee

- Surface finish: mirror finish

- Elongation: 40%

- Yield Strength: 290 MPa

A815 UNS S31803 pipe tee

- Usage: chemical handling pipe

- Production method: forged & heat treated

- Tensile Strength (Mpa): 515

Check the latest stock of 1.4462 UNS S31803 lateral tee in size to 1/2 inch to 24 inches in diameter

ASTM A815 WP-W reducing tee is commonly available in a range of sizes to accommodate different pipe diameters and system configurations. These reducing tees are usually produced by manufacturers in sizes from 1/2″ to 48″ depending on the project requirements.

When selecting the size of the 1.4462 UNS S31803 lateral tee it’s important to consider the pipe sizes and flow requirements of the piping system. The branch size of the tee should match the desired pipe size for the branch connection while the run size should match the desired pipe size.

The dimensional tolerances for SA 815 s31803 butt weld tee are typically specified by the applicable standards or codes. These standards provide guidelines for the manufacturing and dimensional requirements of the A815 S31803 flanged tee.

A straight SA 815 UNS S31803 seamless tee has branches of the same size as the run pipe. A reducing ASTM A815 UNS S31803 socket weld tee, on the other hand, has branches of different sizes compared to the run pipe.